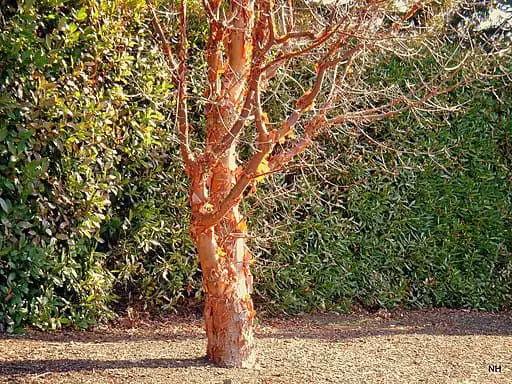

Are you considering Carving Madrone Wood? Madrone has smooth, orange bark, leathery, and magnolia-like leaves. Its wood stands alone and is well-known as the source of charcoal to produce gunpowder. Madrone is a piece of beautiful, fine-textured furniture- and cabinet-class stock with a luster few kinds of wood can match.

It burls when it grows in areas that allow its branches to spread. Use carbide-tipped blades and bits due to the hardness and density of cutting edges. Figured boards require a slow feed into the planer. Do not plane to the exact thickness to allow room for a little sanding.

Failure to do so leads to tearing out. The wood’s density requires special treatment when gluing to avoid joint slippage. A dark-shaded glue is ideal so that any squeeze-out will not show, and allow the glue to set up, then reassemble the parts. Madrone accepts any stain and clear finish you prefer.

Hand-tool carving is not ideal on madrone wood. Power carvers with carbide-tipped cutters work with ease. Avoid switching the grain direction of figured madrone wood because it tears out. Start with medium-cut burs, then change to finer ones. For stability in use, always work wood with a maximum moisture content of 8 percent.

What is madrone wood?

Madrone is a hardwood typically found in the Pacific Northwest region of North America. This wood is known for its reddish-brown color and grain that can resemble burl. Madrone wood is often used for furniture making and other woodworking projects because of its unique appearance. It belongs to the same family as the strawberry tree. White flowers and red berries are characteristic of the madrone tree. Working with madrone wood can be difficult, but the result is often worth the effort.

Madrone wood is a popular carving material. This is because the wood is hard and has a fine grain that can be carved into intricate patterns. The finished product is often beautiful and unique. Madrone wood can also be stained or dyed to create different colors and effects.

Different types of Madrone wood

- Strawberry tree

- Pacific madrone

- Arbutus andrachne

- Texts madrone

- Arbutus pavarii

Madrone wood price

What determines the price of madrone wood is availability. Madrone in limber form is scarce in the rest of the world but comes in different sizes on the Pacific Coast. It comes with a higher price tag, and that is from 4 per board. In some parts, it costs four times the mentioned price.

Burled madrone starts from 2.25 per square foot. Harvesting your wood for woodworking is more affordable, but if you stay in its original state. You can stock and air-dry the wood slowly before any kiln-drying. Failure to do so makes it warp and check. Once dry, it becomes so stable that you will not have problems working it.

Madrone Wood Uses

Madrone has a fine texture and frequent burls for carving multiple bowls into lamps and novelty items. It has been popular in making bowls of smoking pipes. The wood rating is a first-class furniture stock, which makes it ideal for Veneer manufacturers due to figured burls.

Madrone wood identification

Madrone is also known as the Strawberry tree or Madrone wood. It is beautiful and comes in pink and tan colors with red streaks on some parts. However, the green lumber is unstable, so you should be careful when drying it.

Once dry, it has excellent stability. Madrone is hard and a bit difficult to carve. However, you can still have a beautiful, high-polish finish. As compared to European Pearwood, it is superior in grain and workability.

Madrone, also called madrona or madrono, comes from a place that extends from southern British Columbia down to California’s central coast. In that coastal band, there is a forest where you find madrone everywhere in any size.

In rugged mountain terrain, madrone may only reach shrub size, and in rich soil, the tree goes up to 100-foot heights and diameters of 2-4′. You will not have difficulty picking out madrone from the other forest trees. Sometimes you discover an old, graying tree with a small bark that will be smooth and orange-colored.

In May and June, clusters of white flowers hang, and leathery dark-green leaves hang. They fall when new ones grow, which is how the tree stays green. The flowers turn to orange-red and berry-like fruits, representing a colorful tree.

Madrone’s heartwood is a pale reddish-brown and resembles applewood. Its sapwood is cream-colored, and the texture is fine, dense, and hard. The fine-textured heavy wood comes with an irregular pattern of growth rings that presents an attractive wood pattern.

Sanding Madrone wood

You can sand the madrone to make it smooth. However, use progressively finer paper and do not skip a grit; otherwise, you will develop finite scratches. Madrone’s density means pre-drilling for screws and lubricating them with beeswax before driving.

In some cases, it takes several coats of sanding between coats to get the smoothness desired. Madrone wood takes more depending on the wood preparation before finishing as a rule of thumb, and wood through 180 grit before applying any chemical coating, finer if using a water-based finish.

Removing the bark

The bark contains insects and other contents that make it useless in woodwork. Bark removal is a necessary step in wood processing. Start with the first slice of bark and get the cutting edge into it. Go through the bottom using a spud and take off the layer easily. When done, continue with a similar approach for the next bark segment.

Sometimes there is a discrete layer of barks too small to cut with a spud. Slipping the beveled edge of the bark spud beneath the bark can be the simplest method. Push against the handle so that the bark peels away from the wood.

Carving out specific designs

Smoothen the surface of the wood. After sanding wood surfaces, it will be easier to sketch the design on wood. Choose a wood design and transfer it to the piece of wood you are working on. Research the design you want, and sketch it on paper first.

Applying a finish

Madrone is an excellent turning wood that takes stains and finishes well. Sometimes if you are using shellac, there is no need to sand between coats. However, anything you put on wood raises the grain and makes it fuzzy. The finish will be better if you sand between coats.

Dewaxed shellac sometimes acts like a barrier coat over pine knots—the orange shellac ages the finish when finishing new parts on antiques. An oil-based polyurethane gives a beautiful and durable finish to Madrone wood.

Safety tips when handling madrone wood

- Steam the wood before drying to prevent kiln collapse. Madrone is difficult to dry and tends to warp, and steaming gives an even color.

- To avoid oxidative staining during drying, the wood should be dried shortly after cutting.

- Keep your tools sharp for this dense wood.

- Feed rates should be slow and steady to avoid burning and tearing out.

- Nails and screws require pre-drilling

- Use drill bits to avoid skating on the workpiece.

- Sand with care as this dense wood shows cross-grain scratches.

- Monitor clamp pressure to avoid squeeze-out and subsequently starved joints.

- There is no need for grain filling since dyes and transparent colors work best.

- Power carving makes the process easy.

- Avoid using twist drills since they tend to wander off in the wood and cause a breakout. Use a backing board under the workpiece to reduce tear-out.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024