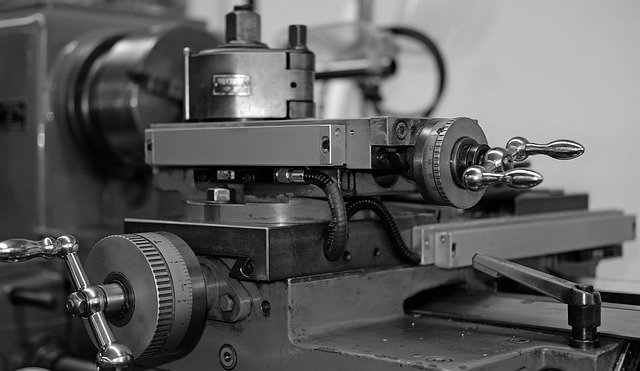

The CNC lathe and Manual lathe differ in improved features and ease of use. The introduction of CNC has enabled the production of a wide range of items in a short space of time. Great innovation comes with controlling machines using computers. Let’s explore CNC lathe vs. manual lathe.

However, this does not mean that the manual lathe ceases to be a great tool. It can be great for starters; it is easier to use, and the instructions can be easy to follow. Below is a more detailed review of both lathes.

CNC Lathe

The CNC Lathe is a more complex machining experience that requires less skill than the Manual lathe. The system can be of best use for complicated cuts. You are not limited to manual work.

A CNC machine is an improved manual lathe that can do all the manual lathe and comes with more improved skills than the traditional lathe. It comes at a price that is not affordable.

A CNC lathe machine is steeper-priced. It requires additional accessories, such as a computer, which is also expensive.

Accuracy and precision are some of the strengths projected by the CNC lathe. The CNC lathe accurately duplicates designs fed to it through a computer. The chances of making errors during the cutting process are very slim. Increased productivity comes with improved machine features. There is less waste involved.

Pros

- Innovative

- Saves time

- More production

- Less experience

- Convenient

Cons

- Not affordable

- Complicated

Manual Lathe

A Manual lathe can be less innovative, but it might be worth having as it gives you a better understanding of how the machine works. You can utilize it to its best capability. You can have a satisfactory experience and easily find better ways to work with the machine.

The early stages of using the machine mean losing more time and resources, but it can be worth it when you start excelling. The level of your skill determines your production. You will need more years of experience in the industry for specific parts of a business. No additional costs are required since the machine does not need a computer or software.

Pros

- Ease of use

- Great performance

- Sharpens your skill

- Affordable

- Allows you to be more involved

Cons

- It is time-consuming

- Demanding

Main Features

- Control systems

- Spindle options

- Gearbox

CNC Lathe

Automatic Control Systems

The lubrication system is amongst the systems. It regulates all the functions of the machine, which is why the machine has long-term reliability.

Boring Heads

It plays a significant role in the woodworking sector. The heads determine a variety of shapes and sizes in large quantities. It helps when the user is carving detailed parts. In industries where craftsmanship is a must, it plays a significant role.

Spindle options

A wide range of spindles attains a high level of efficiency. There is the HSD, and the Perske spindles are excellent for CNC machining.

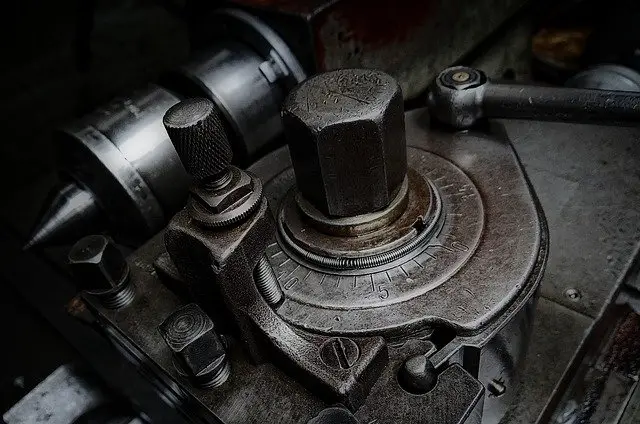

Manual Lathe

Headstock Gears

They are made of alloy steel. It is durable and hardened, allowing you to rub the machine smoothly without making noise. The oil bath lubrication reduces friction.

Spindle

Highly accurate bearings support the spindle. A bigger spindle bore can work better. When you are cutting, the machine remains stable and solid.

Gearbox

It controls the threading capacity. Accuracy in cutting threads can be a strenuous exercise that requires precision. You will need a shear pin fitted onto the machine to eliminate overload.

What could be better?

CNC Lathe

Some tasks require direct involvement, which might be difficult to execute with a computerized machine. A machine that uses the manual system and CNC would have been more practical and convenient.

You could utilize the manual system when you have more orders, increasing productivity. In some instances, a single project requires a simple and light machine. I would recommend a Manual lathe. This will even save your power. Setting up the CNC machine can take longer than you need using a traditional lathe.

Manual Lathe

The accuracy, speed, consistency, and time taken to complete a task could be better when using the machine. Understandably, you will work manually, but making the same design on different items would be better. The instructions could have been more precise and innovative. There could be a way to lessen the workload, even manual work.

Similar Features

- As much as the manual lathe requires a more skilled user, both machines need increased productivity skills.

- The machines can execute heavy-duty activities.

- Even if the CNC is controlled using a computer, it still involves the user in cutting.

- Both machines work on various materials, such as metals, plastics, and glass.

Key Differences

When using a manual lathe, you need skill to master the cuts, whereas less skill is needed when using the CNC lathe. A Manual lathe requires you to master your cuts so that when you are required to execute a specific cut, you do not stumble. Unlike the Manual lathe, the CNC uses computers to do the work.

The Manual lathe takes longer because you need more time to be an expert. You will have to use more resources in the learning process. When you want to save time, I would recommend the CNC machine.

A Manual lathe is difficult to use when you are after consistency and perfection. Cutting multiple parts of the same style can be hard to maintain. Your clients might understand a certain degree of variation, but you will notice some differences. This can affect your business.

Items that need to be similar in every bit need a computerized lathe. It needs careful cutting and precise measuring. Attention to detail is another prerequisite. This does not mean making more similar items using a manual lathe is impossible. The process will take more time as you try to be precise.

The CNC can be the best machine for items that need more accuracy because it is easier, more accurate, and faster. Considering all the features of the CNC, one can justify the cost. A matching computer will be appropriate for the software.

This will also attract an additional cost. I would advise you to save before buying the machine and the computer. No accessories are required when you are using the manual lathe. It is more affordable.

Final Verdict on CNC Lathe vs Manual Lathe

I recommend the CNC lathe for more precise, fast, easy, and increased productivity. If you are the type of user who is always busy and wants to produce more items quickly, then the CNC lathe will be more advantageous. If you like to explore more practically, you may use the manual lathe for a satisfactory experience.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024

Thanks for clarifying that it’s not the computer doing the cutting but the craftsman himself when it comes to using a CNC lathe. I’m interested in looking for a CNC lathe machine shop service soon because I’ve been planning to have one of my large table redesigned. getting new legs for it will surely require a good lathe.