What’s it going to be, CNC Machine vs 3d Printer? The development of durable materials requires a perfect machine for precision. The introduction of the CNC machine is a way to explore printing on different materials. These two machines have similarities and differences that separate them.

As much as 3D printing saves time and money, CNC machining still has its strengths in some key areas. So you can choose the best of both, depending on your needs. The evaluation below will guide you to your best choice between the two products.

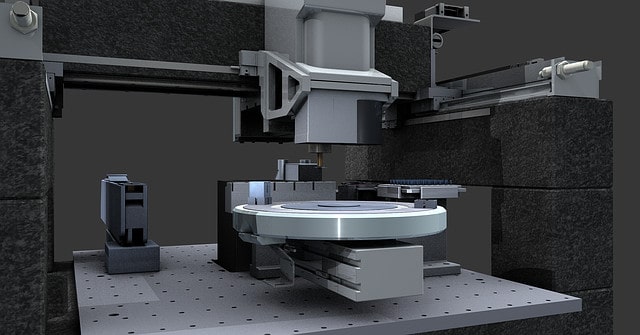

Overview of the CNC Machine

The CNC machine starts with a block material called a blank that cuts off material to make a finished part. The cutter and spinning tools shape the piece. It works with accuracy on wood, metals and plastics. The CNC machine focuses on ABS, Nylon, Polycarbonate, Acrylic, Polypropylene, POM and Peek plastic.

Aluminum is also used by the CNC machine. It uses steel, magnesium, alloy and brass. It is recyclable and effective. The CNC machining requires your hand as it runs the material. It requires a skilled operator to choose the perfect tool, rotation speeds of the tools, the cutting path and repositioning of the material you are working on.

Your contribution does not end there. You offer post-processing skills that take more time. You can hardly multitask when you are using the CNC machine. The CNC machine is efficient on large sizes of material. CNC machines like the CNC Lathe are used for mass production. It has a way of tolerating dimensions.

Pros

- Great dimensional accuracy

- Compatible with multiple materials

- Increases production volume

- Ideal for complex tasks

- Safe

Cons

- Not affordable

- It requires your hand when in use

Key Features of the CNC Machine

Control panel

It is amongst the CNC machine parts used to set the program for activities done on the workpiece. It allows you to have control over the machine. That is where you change settings and control your speed. The operation code is fed into the machine via the control panel to run automatically.

Pedal

The pedal, known as the foot-switch, is where the operator opens or closes the chuck for gripping. It is operated the same way you do a tailstock. The material needs a grip, other-wise it will slip away.

Chuck

The chuck is onto the main spindle. It makes sure that your workpiece is in the correct position.

Tailstock

It brings extra grip to the workpiece. Chances are low that it will move from the position as the machine runs. It comes with the tailstock quill, a setting the workpiece needs between the centers.

Headstock

That is the heart of the machine that fixes the material. It comes with a motor that drives the main spindle.

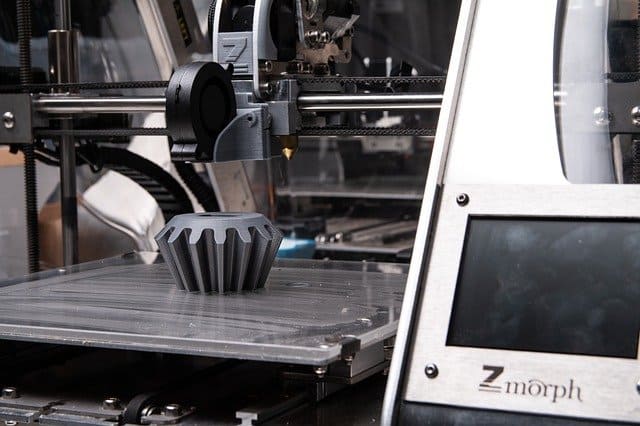

Overview of the 3d Printer

The 3D works on parts created layer-by-layer using multiple materials. These include plastic filaments, resins, or metal powders. The source of energy used is the laser or heated extruder. It works in each material layer and is solidified to form the finished part.

3D printing focuses more on thermoplastics such as ABS, PLA and Nylon. It also uses photo-polymers such as wax or calcinable. On metals, it uses aluminum, stainless steel, titanium and Inconel. Some 3D printers work on sand or ceramics. However, printing using 3D comes at a price.

The 3D is easy to use. You must prepare the file once, choose the part orientation, and support if needed. You will not need to do a manual task when the machine starts printing. All you need to do is wait for it until it is done. 3D printing creates parts with high geometric complexity.

Pros

- Innovative and accurate

- Freedom of shape

- It works on multiple applications

- Fast speed and cuts costs

- Lightweight parts

Cons

- Not ideal for mass production

- Limited in speed and accessibility

Key features of the 3D Printer

Speed

The 3D has the Rapid Prototyping technology. That is a process whereby you design, manufacture and customize a part in a short space of time. The saw design depends on speed, and the user has the freedom of creativity. The machine is ideal for small businesses and DIY enthusiasts.

Build volume

The machine is flexible, and it has a way it creates or working on parts that fit within its stipulated build volume. Unlike traditional machines, it allows complex geometry. Designs are in the slicer software and will be without additional changes inside the machine.

Functionality

The 3D printing needs you to follow the step-by-step assembly of each part. The Fused deposition modeling makes objects layer by layer, starting from the bottom and heating the filament. That enhances the design and improved quality parts.

Layer thickness

Layer thickness is about the surface finish of a part. The material cannot be predicted. It comes in multiple forms. Hence your machine has to be versatile to deal with that.

Speed

The maximum speed to run your machine is not standard. What determines speed is the height of the part and the build quality of the part.

Accuracy

There is no need to assume the thickness of parts since they come in different forms. That means you cannot universalize accuracy. What determines the accuracy on your part is length, geometry and orientation.

Similarities

- The CNC Machine and the 3d Printer are compatible with multiple materials such as plastic and metals.

- They are both limited by the tool size.

- They both have service temperature limits.

Differences between CNC Machine and 3d Printer

- 3D printing is a form of additive manufacturing, whereas CNC machining is subtractive. That means the CNC machining trims away material to make the finished part. Cutters and spinning tools shape the material. 3D printing revolves around using materials such as plastic filaments or metal powders.

- 3D printing focuses more on plastic, whereas the CNC machine focuses on metal.

- The 3D is easier to use than the CNC machine.

- When using the CNC, you need to operate the machine, whereas 3D printing is left alone when printing.

- The CNC machine is more tolerant than the 3D.

- The 3D printer in the SLS and DMLS is weak in build volume compared to the CNC machine.

- The CNC machining is more effective on parts that demand extra smoothness than the 3D.

- CNC machining is faster than 3D printing.

Cost

3D printing is more affordable than the CNC machine. The 3D printers differ in price depending on levels. If you are a beginner, you can have from 200 to 500. Higher-end machines range from 1,500 to 6,000. The CNC machine ranges from 1000 to 3000 for hobbyists, but for hardcore users, it ranges from 5,000 to 500 000.

Verdict on the CNC Machine vs 3d Printer

There is no perfect product between the CNC machine and the 3d printer that is universal. Both machines excel in performance as they come up with innovations. Depending on the material, geometric complexity and budget, you should choose a machine that suits your needs. 3D printing is very innovative and offers excellent freedom in shaping. It saves time and still delivers high-quality materials for industrial production.

CNC machining has high dimensional accuracy, although it requires physical effort while using the machine for many functions. However, it is not strong enough to support mass production. It is limited in terms of speed and accessibility. I recommend the CNC machine for materials that need to be especially smooth. If you are on a tight budget, I recommend the 3D printer. Check out our post on the best CNC machine for woodcarving.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024