Difference between a jointer and a planer

Wondering what the difference between a jointer and a planer is? A jointer is a machine that allows you to straighten the edges of boards. It does this by passing the board over a series of blades that remove any uneven edges or bumps, creating a straight surface. On the other hand, a planer is a machine used to plane boards. It releases small amounts of material from each side of the board until it reaches the desired thickness. This article looks at other differences between these tools.

They are used to fix the surface of the wood. Jointers perfect the edges and smooth the wood, while a plane maintains a certain surface thickness. A jointer cuts the wood from the bottom, while a plane cuts from the top. Other features that distinguish the two tools can be found below. So, onto jointer vs planer.

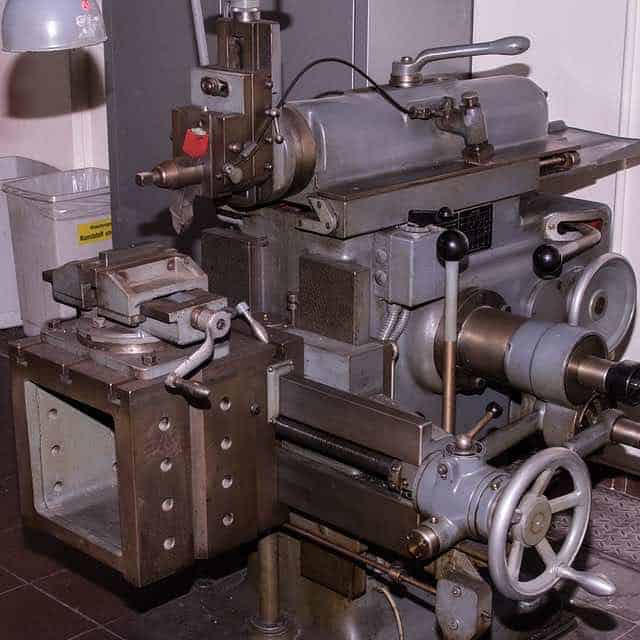

Jointer

A jointer is a wood machine that removes bent surfaces from wooden surfaces. It is used to join wood pieces and create long items.

I would not let go of a short cutting board and buy a new one when I can extend the one I have. You might have a damaged cupboard door that needs an extension. That does not mean you must destroy the whole unit to install a new one.

That is where the jointer comes into the picture. You might need a Jointer so that you work on uneven wood pieces. They are difficult to join. A warped or twisted item can be a result of storage conditions.

The jointer removes the uneven part and levels up the surface. You might ask what differentiates using a hand plane from using a jointer. A Jointer does not work manually. It has a motor that does not require the user to exert more effort.

You might not spend more time working when you master the required skill. As you use the jointer, a bit of skill is required. It may take more time for you to be an experienced user. When you master using the tool, you can be quicker than you imagine. The limitation of a Jointer is that you are not guaranteed consistency in thickness.

Pros

- Requires less effort

- Saves time

- Easier

- Adjustable

- Affordable

Cons

- Requires skill

- Lack of consistency

Planer

A planer smoothens surfaces, making joining or using the wood piece easier. When you finish the warps and the cupping, you might need a smoothened surface to quickly and easily join two wood pieces. You might need to get rid of unnecessary surfaces and edges. This is why I would advise you that you can finish off the surface using a planer.

You might opt for the jointer only, as you will run the surface several times until you achieve the preferred texture. This will take a lot of time and effort.

I would not want to spend more hours working on a single piece of wood when I could spend half of the time. An additional machine will attract an additional cost, but it is worth it.

You can also choose to have just the planer, but the challenge comes with how best you will ensure the surfaces are leveled. A planer does not need a skilled woodworker. There is a flatbed that you can put your board on top of.

The rollers determine the board’s speed through the cutting head. The machine’s main characteristics are smoothness, precision, and consistency. Unlike the jointer, which can smooth the workpiece through multiple runs, a Planer cannot eliminate warps and twists.

Pros

- Ease of use

- Consistent

- Smooth

- Convenient

- Great finishing tool

Cons

- It is not affordable

- It cannot remove warping or twists

Features

- Design

- Cutter-head

- Bed-width

Jointer

Design

The planer is box-like. The jointer has two coplanar tables with a cutter head in the middle.

Cutter-head

The rotating cutter head cuts from the top of the wood. The wood goes over the cutter head.

Bed-width

The standard width is 6 inches, but you can have more. It is enough for a wide range of wood surfaces and can withstand both soft and hardwood.

Planer

Design

A Planer comes in a box design. The rollers take your board from one side of the machine to the other.

Cutter-head

Unlike the jointer with a cutter-head that cuts from below, the planer has one that cuts above.

Bandwidth

The thickness on a Planer could have been better. However, it can withstand the minimum pressure that comes with smoothing surfaces.

What could be better?

Jointer

- Consistency could have been mastered using a Jointer.

- The tool could have been more accurate and innovative so that less skill would have been required.

Planer

- It could have been able to get rid of warps and twists

- The manufacturer could have accommodated users with a tight budget.

- A flat surface could have been placed downwards so the tool would eliminate the top layers.

- Pressure rollers could have been substituted with rollers that take away warps.

Similar features

- Both tools work on wood pieces by removing the rough surface and transforming the deformed piece.

- Rotating cutter-heads

Key Difference between jointer and planer

- Jointers are used to square and flatten edges, whereas Planers are used for thickness and making parallel surfaces. The thickness of the surface has to be the same.

- A Jointer straightens the surface when an item is twisted or bent. It also eliminates cup warps.

- A Planer is accurate in terms of thickness, whereas a Joint is not precise on thickness.

- Planners cut wood from above, whereas a Jointer cuts from below.

Final Verdict

Choosing between a jointer and a planer is very difficult. The two tools usually work better together than individually. In the initial stages of woodworking, you will need the services of a jointer, while you can finish the job with a planer.

You need a jointer first because it flattens and straightens the edges of the piece of wood. If you want to perfect your edges in terms of thickness, the planer may be the appropriate tool. However, if you can not have both machines, I would advise you to use the planer because it will give you uniform surfaces with the same thickness, size and shape. What will it be, planer vs jointer?

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024