How to make a cyclone dust collector

Building a cyclone dust collector with clamps makes emptying the bucket quick and easy. LED lighting increases visibility during the project, so you can easily tell when the bucket is full. Building a vertical dust collector takes up less space in your workshop. The material you use to make the best dust collector depends on your budget. You can have a high-quality cyclone dust collector even with a low budget, and a low budget will attract a plastic cyclone dust collector.

Materials

- Plywood 5/8 inch.

- Cyclone dust collector.

- 5 Gallon/bucket.

- Hinge.

- Clamps.

- Casters.

- Spray paint.

- Central Vacuum System.

- Vacuum pipes.

- Coupling.

- Pipe clamp.

- Joint Cement.

- Rubber coupling with clamps.

Steps

- Gather your materials and prepare your workspace. The plywood does not have to be necessarily new. Make use of leftovers if you have them.

- Draw a design of your choice. Even if you are a beginner, you have an idea of what you want. That helps you not to forget to group your pieces and make changes. You have the chance to see all dimensions in 3D.

- Start assembling all wood parts. Put the foam tube around the bucket before you start on the middle shelf. A tight seal between the bucket and the top shelf makes the system start working. That is why you have to insert the tube first.

- Add the cyclone adapter. Make a hole for the cyclonic adapter using a hole saw or a jigsaw. Do not worry if the drilled hole is not perfect because it is not visible.

- Start preparing to assemble vacuum pipes. When assembling, do not forget to glue the pipes so they last longer. Central vacuum pipes are more affordable than other models. Get them from local hardware stores.

- It is now the time to add colors. Use spray paint on the dust collector.

- Start installing the remaining parts and screw the cyclonic adapter in place. Add the toggle clamps and the casters.

- Attach the LED light system. It helps you see when the bucket is full with ease. The lights used are automotive. That means they are both waterproof and dustproof. Run a test on the LED system. Finally, you have a fully assembled cyclone dust collector. You have the debris going in the bucket, and not often.

Why build a cyclone dust collector

- A cyclone dust collector is cleaner and safer than standard collectors. There is a big cloud that comes from the collection bag when removed. There are only heavier chips and debris when using the cyclone’s primary collection point. That does not produce much dirt.

- The cyclone dust collector does not allow the dust particles to be in contact with the filter. That is why the frequency of cleaning or replacing a filter is low.

- The amount of dust removed from the fixed filter screens is amazing.

- There is minimal maintenance of the dust-collection equipment. Make sure you empty and replace the bag or bin that catches the dust.

- Performance problems are taken care of due to maintenance delays. Sometimes the filter housings are not installed after some maintenance.

Parts you will need

- Shop-vac.

- 5-gallon bucket.

Tips for construction

- Use water to reduce dust construction. It prevents dust particles from flying around. That reduces the chances of infecting workers with dust-related diseases. Using a sprayer truck misting the area costs extra, but it is worth it. It keeps the soil damp. However, watch out for excess water that leads to erosion.

- Using a Dust Extractor vacuum traps more dust and takes care of plaster and concrete. The vacuum picks up construction dust and harmful debris. The product is compatible with handheld power tools, making it convenient.

- Using dust separators makes the removal of 93.3% of construction dust possible. It also extends the life of the extractor and efficiency. The dust machines last longer without having to clean and empty dust compartments.

- Air scrubbers capture dust from the workspace once it becomes airborne. The scrubber vacuums the dust from the air and filters it before sending it out the window. Consider using this method for indoor construction for maximum performance.

- Dust barriers keep dust away from the working area to a non-workspace. The barriers are also known as zip walls since they keep the dust in one area. There are low chances of having the pollutants moving around the workshop. You determine how the dust moves from room to room. Add the barriers accordingly, and the dust has to escape from the workspace. Containing dust makes it easy to control it.

Considerations

Dust Control Needs

The size of the cyclone dust collector system has to match the volume of airflow required to capture and convey particulates to it. The volume of the particulate contaminants has to match the product size. Make a cyclone dust collector that meets your needs.

Budget Considerations

The needs of the cyclone dust collector determine the amount you will spend on it. The type and size of the dust collector matter. The cyclone dust collector can be affordable, depending on your choice. Avoid paying attention to the cost but to quality and performance. Look at the maintenance costs. Cleaning the machine alone reduces costs.

Pre-Filtering Needs

Dust and particulate collection efficiency depends on the airborne particles’ size and distribution within the air or gas stream. Look at the size of particulates circulating in the workshop before you make the cyclone dust collector.

Health Benefits

Before you make other considerations, safety comes first. How much dust is trapped is why having a collector and the workspace has to be dust-free. Be aware that their multiple chemicals in the materials you will be working on that you cannot afford to inhale.

FAQs

How do you design a cyclone dust collector?

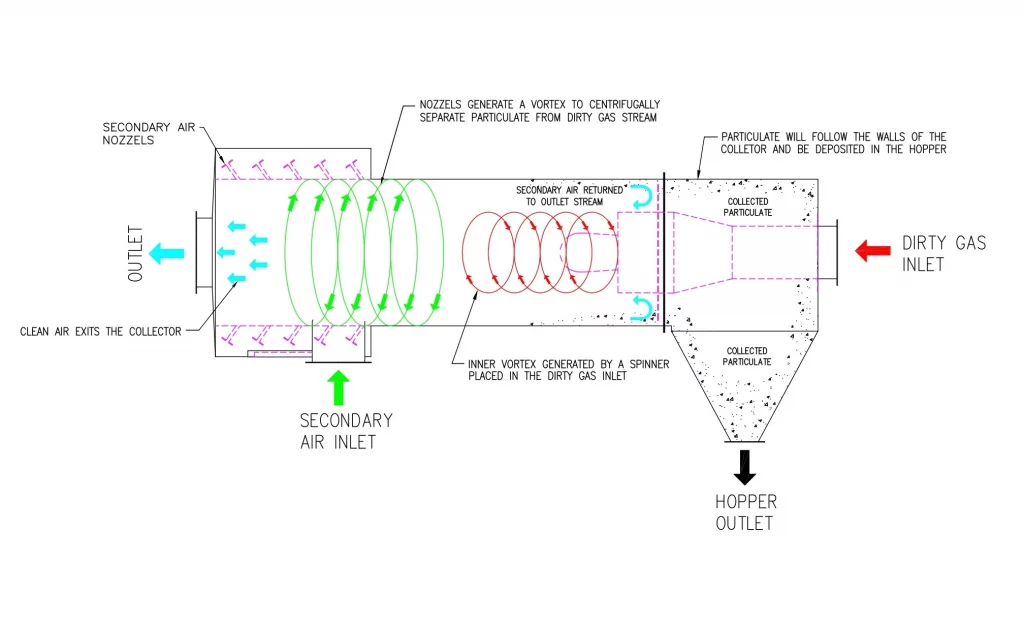

Make a design for the dust collection machine to collect the dust of polyurethane material removed during the grinding operation. The dust collector’s inlet is near the lathe machine’s carriage. The cyclonic process of air involves collecting dust near the dust collector machine.

What is a cyclone dust collector?

These are two-stage collectors that come with two collection points. It captures dust and debris from your workspace just like any other collector, but it has advantages that make it unique.

Video Tutorials for making a cyclone dust collector

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024