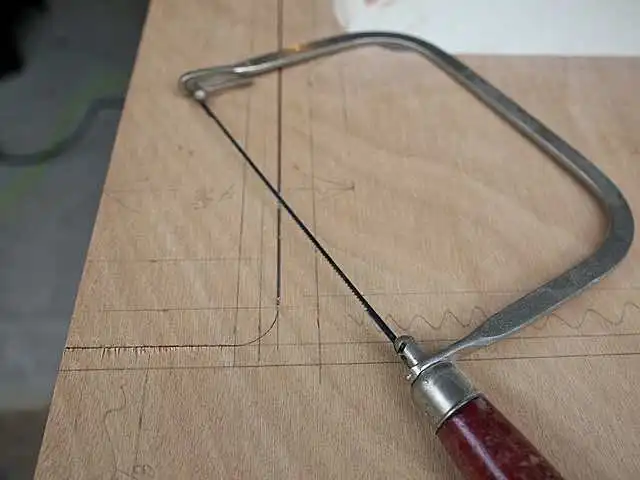

The fret saw blade is one of the most important in the toolbox of woodworkers. It cuts and smoothes wood in a way that no other saw blade can do. It is good to maintain your scroll saw blade if you want to keep your saw blade sharp. There are several ways to do this. The first way is to use a saw blade sharpener, and the second is to use a stone sharpener.

Loosen the socket with a screwdriver

Make sure that you unplug the saw. Take the screwdriver and loosen the socket. That exposes the head of the socket. Trying to start the process while the saw machine is on leads to injuries.

Use your right hand to hold the lock on the motor. That keeps the blade from spinning as you loosen the bolt. You should know the difference between a screwdriver and a hex wrench. A hex wrench damages the edges of the socket in the head, and once they are damaged, it is impossible to seat correctly.

Remove the socket and set it aside. You must know the correct type and size of the right screwdriver. Failure to do so damages your socket. The moment you damage it, you are throwing it away. You now have a double task. That includes replacing both the socket and the blade.

A screwdriver allows you to loosen the socket with ease. Already changing coping saw blades is easy and using a screwdriver is easier. Over-tightening your screwdriver breaks the socket head.

Unscrew the retaining bolt

The blade is removed by unscrewing the handle partially. You stop the saw blade from rotating by using a steady bar where the blade is attached. A perfect alignment of the bars keeps the saw blade straight. The handle controls the blade tension and locks it at a certain angle of your choice.

The bolt attaches the slots to the arm. It secures the blade. You have to unscrew the bolt in an anti-clockwise direction. When the saw blade is not hard, unscrew it using your hands. You are also allowed to use a screwdriver. Be careful before you lose the bolt. Keep the bolt safe as you handle the old blade.

Remove the old saw blade.

When removing the old blade, you do not need much effort. A slotted pin on both ends holds the saw blade in place. Squeeze the saw by flexing it and unhooking it from both ends. The way you take out the saw blade is the same way you install the new saw blade.

The difference lies in the direction in which the screws are secure. Make sure that the saw machine is off to avoid accidents. The blade teeth are dangerous hence you need caution. They are already facing you, and that is why I advise you to put on gloves. Two metal arms hold the blade from both ends of the frame.

They have thin slots that you insert your blade in. You must loosen the two slots so that the saw blade comes out. You need to apply a bit of force on raising one end of the arm so that it lets the saw blade loose. Stretch the saw blade as you take it out. Bear in mind that there are more dangerous technical faults on the saw blade. Some pins protect the saw blade from falling out. That is why you have to pull it out.

Removing the blade involves turning the handle in an anti-clockwise direction. You must stop turning the handle when the saw blade releases from the frame’s arms. After removing the blade, set it aside not to mistake it for the new saw blade. Leaving it lying around can cause an injury. It also disturbs you from running the process.

Install the new blade

Before installing your new blade, ensure the blade teeth are facing towards the handle. Hook the saw blade on and release the pressure you put on the saw so that it snaps back to its original position. You tighten the new blade by twisting the handle. Some coping saws have knob screws.

You have to tighten the knob screw. Make sure the new blade is not dull, just like the old one. Insert the new saw blade into the loosened slots on the frame’s arms. The teeth have to be outside of the frame. Some users prefer buying used tools. If installing a used blade saw, check the parts that make it. These include teeth and sharpness.

It has to be the exact saw blade as the one that you were previously using. Do not tamper with the wrong blade saws. They either damage your saw or hurt the user. However, you may consider a different blade if the old one was not the right blade saw. Seek professional help if you are not sure. You have to contact the manufacturer of the model you are using for the right blades.

Bear in mind that specific blades work with different materials. Installing a new saw blade does not mean a problem with the old one. You may want to switch blades. When installing the new saw blade, do not touch the blade’s teeth using your bare hand. That is when protective clothing in heavy-duty gloves comes into play. If you do not have one, avoid touching the blade.

Tighten the new bolt

You must turn the handle clockwise to tighten the blade’s tension. The pins have to be far apart from the saw blade so that you fine-tune the tension. There will not be a need to hold the saw blade to stay in place. It does not matter if tensioning the blade takes a complete clockwise rotation.

You have to stretch the blade tight enough to start using it. There are coping saws with levers that allow you to adjust the angle of the blade. Release the blade tension to use them. Turn the levers in the direction you want the saw blade to face. You now tighten the saw blade. Avoid over-tensioning the saw blade, as that results in the blade snapping.

Under tightening, the saw blade damages the saw tool and injures the operator. Overtightening the new bolt also breaks it or causes inaccuracy. That is why you must maintain a standard tension that is neither too tight nor too loose. Test the blade and make sure you have protection from the small particles made during cutting.

Conclusion

Most coping saws, or coping saw blades, are made of steel and replaced once used for many years. The method outlined above allows you to replace your coping blade with minimal fuss. Find out about the best coping saw.

Video Guide

Recommended Blades

IRWIN Tools Coping Saw Blades, Coarse, 3-pack (2014500)

Olson Saw CP30800BL Coping Saw Blade, 24-TPI

OLSON SAW CP30000BL Coping Saw Blade Assortment

Stanley 15-059 Coping Saw Blade, Pack of 4

FAQs

How do I remove a coping saw blade?

To remove the blade, squeeze the saw so it flexes and the blade is no longer taut.

How do I hook on my new coping saw blade?

When attaching your new blade, ensure the teeth point toward the handle.

What is a Back Saw?

Tenon and dovetail saws are often referred to as ‘back saws’ because they both have a metal or wooden spine running along the back of their blade.

What is a fretsaw?

The fretsaw is a saw used for intricate cutting work, often incorporating tight curves.

What are the different types of teeth blades?

There are two significant kinds: wood blades and metal blades.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024