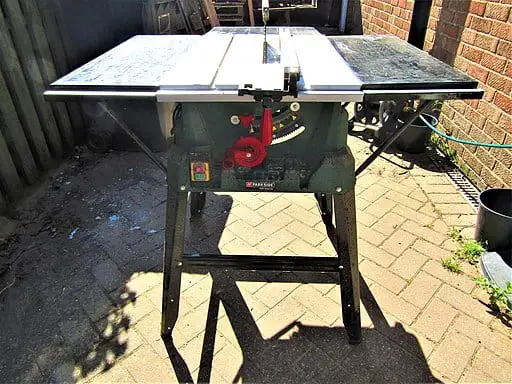

The difference between a table saw and a contractor saw lies in the vibration level during use, size, power, noise level and robustness. It comes down to comparing the two to match each of them to your needs. Below is a more detailed summary of both saws, their advantages and disadvantages. You can also read our review of the best table saws for contractors.

Table saw

A table saw withstands longer and wider materials, and it is ideal for materials that require longer cuts. There are table saws with additional shelf space, and it has onboard accessory storage that keeps extra blades, the miter gauge, and the rip fence.

That brings convenience to the user when you need to replace your blade. Some industrial table saws have large surfaces and workbench table saws are ideal for DIY enthusiasts. The solid base makes the tool sturdy as it stays in place.

You connect your tool to a dust management system that keeps you healthy from diseases caused by inhaling saw dust. The blade on a table saw is fixed. The height is adjustable as you raise it lower or higher, depending on the thickness of the wood you are working on.

The blade is stationary. For accuracy, the blade guard and rails guide the material. There are four types of table saws. These are the bench, contractor, cabinet, and hybrid table saw. The contractor and the cabinet table saws are portable for household activities.

The cabinet table saw combines the two, and the hybrid table saw is heavy-duty. Table saws have different price tags. They range from 250 to 5,000 depending on your budget and working conditions.

A table saw makes Crosscuts, ripping cuts, dado cuts, bevel cuts, fine rabbets, grooves cuts, and kerf cutting. Use the right blade and keep the saw clean and the environment. Every saw cut requires a supplementary tool.

Pros

- Table saws are available on a variety of price tags. They range from 250 to 5,000 depending on your budget and working conditions.

- Onboard accessory storage.

- Adjustable blades.

- Accurate.

- Effective dust management system.

- Specific table saws for different locations.

Cons

- High noise level.

- A bit unstable.

Features

Motor

The size of the horsepower determines the cutting power. Light bench saws work with the 3/4hp up to 1.5hp. They cut up to 5/8 inch thick material. Large table saws come with 2hp to 5hp motors. The cabinet table saw is compatible with the 5hp motor saw. The Dewalt 10-inch table saw has a 15A high torque motor powerful enough to cut through treated hardwoods.

Blade size

When manufacturers name a table saw, they are after the blade size. Table saws come with circular blades; the 10-inch is the standard blade. The blade is adjustable depending on the material you are working on. The Dewalt 10-inch table saw uses a 10-inch tooth carbide blade that makes fast and smooth cuts.

Fence options

The fence is the adjustable guide of the saw. It makes your material stay in place. The T-square is the standard fence that is ideal for the cuts. Specialty fences have a micro-adjust feature. The Vega U26 Table saw has micro-adjustment table support (Source). You are allowed to fine-tune the measurements of the cut.

Rip capacity

The rip capacity ranges from 18 inches for entry-level to 60 inches for high-end saws. I recommend a table saw that rips materials with accuracy. However, it also depends on the ideal materials you will be working on.

Contractor saw

A contractor saw is heavier than benchtop saws and has a heavier duty. It comes with a larger table and an induction motor that does not use brushes. The saw motors do not make noise even if the wood is hard, and you cannot even tell the hardness of the wood from the saw’s performance.

The contractor saw motors use a standard 1-1/2 to 2 horsepower, with a 115-volt amperage. Almost all contractors’ saws have motors convertible to 230-volt use easily—the contractor saw’s weight range from about 280 pounds down to 220 pounds.

They come with different extensions from cast iron, solid or waffle pattern, or laminate-covered manufactured wood or pressed sheet metal. A contractor saw is lighter than a cabinet saw, and however it is heavier than benchtop models.

The motor drives the saw blade through a single belt, which increases the cut’s depth. Such a mounting also isolates the blade assembly from much vibration, which explains how the saw is more comfortable.

It also produces smoother cuts. Fences range from average to excellent. However, you can still change the saw fences as you go for aftermarket models meant to increase the efficiency and accuracy of table saws.

Trunnions are attached to the table from the underside and made of cast metal. Some trunnions of aluminum, and that does not compromise durability. However, it comes with its limitations. It cannot cut thick, heavy hardwoods. It is underpowered but ideal for hobbies.

Pros

- No noise.

- Multiple extensions.

- Increased depth of cut.

- Affordable.

- Precise.

- Versatile.

Cons

- Heavy.

- Underpowered for thick cuts.

Features

Fence

Your budget dictates how good your fence is. Look for a saw fence that is parallel to the blade. It is smooth and accurate when adjusting. Most contractor saws have decent but not perfect saw fences. You can always upgrade your saw fence.

Miter gauge

Most contractor saws have a decent miter gauge, but you can still buy a separate one. When deciding on a saw, put the miter gauge into the miter slot and try to wiggle it sideways. It has to fit snuggly; if they wiggle much, change it.

Motor size

Standard contractor saws have either a 1 1/2 or 2 horsepower motor. The contractor saw’s 1 1/2 or 2 horsepower motor is powerful enough. Feed the wood slowly and use a very sharp carbide-tipped blade.

Saw blade

Standard saws have a 10-inch blade, but some high-end saws have a 12-inch saw blade. Both work just fine on most tasks. What matters most is the quality and finish of the saw blade rather than the size. Numerous blade designs ensure the best cut. Different blades for cutting dados, plywood, plastic laminates, and other materials exist.

What could be better

Table saw

- It could have been more sturdy.

- The vibration could have been lower.

Contractor saw

- It could have been lighter.

- It could have been strong enough to cut through a thick wood.

Similar Features

- Adjustable.

- They are both portables.

- Versatility.

Key Differences

- A table saw makes noise, whereas a contractor does not.

- A contractor saw is more stable than a table saw.

- Although they are portable, contractor saws are a bit heavy.

The verdict

As much as the above saws have similarities, the differences make each unique. Contractor saws can match your pockets if you are on a low budget. For longer and broader materials, make use of the table saw. That leaves the contractor saw for hobbyists. For a quiet neighborhood, you might consider a contractor saw. Both still make great candidates hence the need to match your needs.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024