Wood and metal lathes are the two most common types of lathes. The main difference between them lies in their construction. A wood lathe is designed for machining wooden workpieces, while a metal lathe is used for workpieces made of metal. Wood lathes are usually smaller and simpler than metal lathes.

Metal lathes are big and a bit complex. When you want to get a lathe, you need to consider the type of material you will be working on. However, a universal machine might be inconvenient. Below are some notable differences between the Wood lathe vs Metal lathe.

Differences | Wood Lathe vs Metal Lathe

- A Wood lathe works on wood, whereas a Metal lathe works on metalwork. However, the Metal lathe still works on wood.

- Wood lathes are smaller than metal lathes.

- Metal lathes are a bit more complex than wood lathes.

- A Wood lathe is more affordable than a Metal lathe.

- The Wood lathe can work easier without mounting, unlike the Metal lathe, which is too heavy to use as a free-hand cutting tool.

Similarities

They both use the same system when it comes to operation. The work piece has to be attached to the lathe. It does not matter which type of work piece you are working on. The reason why it has to be attached is that it has to rotate against the cutting tool.

What is a Wood lathe?

A wood lathe is a machine that is meant to shape wood material. The cutting process revolves around drilling, sanding, and deforming wood pieces. You must ensure the wooden piece rotates against the cutting tool to expose the unwanted part.

Exposing tough materials to the cutting tool will not lead to a successful process. Simplicity is one of the characteristics that describe the wood lathe. It does not take much of your space as it is small.

The pulley system regulates the speed at which the lathe runs. Although effective and efficient, it does not give more power than the Metal lathe. The wood machine might not need mounting.

You can use it as a mobile machine. That makes it easy to put away as soon as you finish the task. You can detach the head in a short space of time. Although it is difficult to use on hard material, you can still use it to cut light plastic material.

You can even have a detachable power motor attached to the Wood lathe that you can use on hard material. It can be innovative as you can make it a computer-controlled machine.

Pros

- Simple

- Small

- Effective pulley system

- It is used as a hand tool.

- Light

Cons

- Less power

- Not effective on hard materials

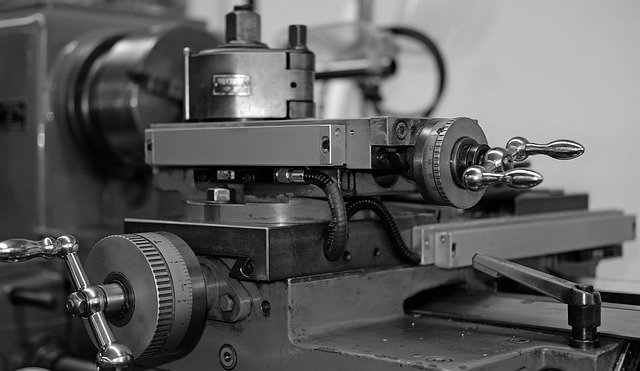

What is a Metal lathe?

Unlike the wood lathe, the metal lathe works in metalworking applications. Metal is harder than wood. This is why a wood lathe might be unable to cut through hard material. This shows why the Metal lathe is a powerful machine. It easily deforms hard materials such as steel, iron, and aluminium.

It is ideal for manufacturing materials. The cutting tool is hard enough to withstand the pressure of metalwork. The cutting tool has to press against the metal piece that is fixed onto the lathe. The workpiece will rotate against the tool that cuts through the material. The spindle tends to be slow because cutting through metal takes time and is not easy.

Chances are slim that you will operate the machine at a maximum speed. The machine is quite sturdy and solid, which makes the experience bearable. It would be best if you were an expert working with the metal lathe, as it requires precision.

When looking for accessories, you need to choose mechanically controlled tools and powerful motors, which is why it is heavy. It can be a good tool for industrial machinery and military weapons.

Pros

- Hardened cutting tool

- Extremely powerful

- Sturdy

- Precise

- It can be mounted

Cons

- Complex

- Slower spindle

Main Features

- Headstock

- Spindles Gear speed control

- Tailstock

- Carriage

- Bed

- Handwheel

Wood lathe

Motor and Speed control

The motor is located on the left side of the lathe, in the headstock. Depending on the type of motor, it can be covered or not. I would go for a closed one, as it will be more secure. The motors range from ¾ to 2 HP.

Tool rest

The purpose of the toolrest is safety. You can adjust the angles from which you can shape your wood material. Switching tool bits is made easier and quicker, which might be great for users with heavier workloads.

Metal lathe

Motor and Spindle

The motors range from 1/8 up to 3HP, which shows that there is a wide range of motors. They have a speed control dial, which makes the activity quick and easy. You can use it to turn metal pieces that require different speeds.

Tool-rest

Just like the Wood lathe tool rest, it is a four-position-tool-rest that allows you to place any four tools in different positions you will be using. That makes switching tools easy.

Cost

A wood lathe is more affordable as it tends to be simpler and lightweight. A Metal lathe comes at a steeper price as it falls under the industry-mechanic grade. It comprises complex systems and features that attract an additional cost.

A 22″ x 42″ 3 HP, 3-phase motor wood lathe from Grizzly will set you back at just under $2500. In contrast, an 11″ x 26″ 1 HP Single-Phase metal lathe is within the same price range. Wood lathes from Grizzly start from under $500. You would be hard-pressed to find a metal lathe in that range.

Conclusion

In summary, both machines work well when the right material is used. Although the wood lathe is simple, affordable and lightweight, chances are slim that you can use it for metal parts.

In contrast, you can also use the metal lathe to cut wood. This makes the metal lathe a versatile tool that should not limit you to various materials. I recommend a universal tool that can hardly select a material. Your application should determine the type of lathe you buy.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024