Is tulip wood good for carving

Tulip wood carving is an architectural carving that has been done on various types of wood since the 1800s. Tulipwood is a softwood sometimes referred to as “soft maple” It was originally used to make furniture but is now used by veneer makers, wood turners, and wood carvers for wood sculpture. We all have that one friend who has a passion for carving. They love to take a piece of wood and turn it into a fantastic piece of art. This article will show you exactly how to carve Tulipwood.

What is tulipwood?

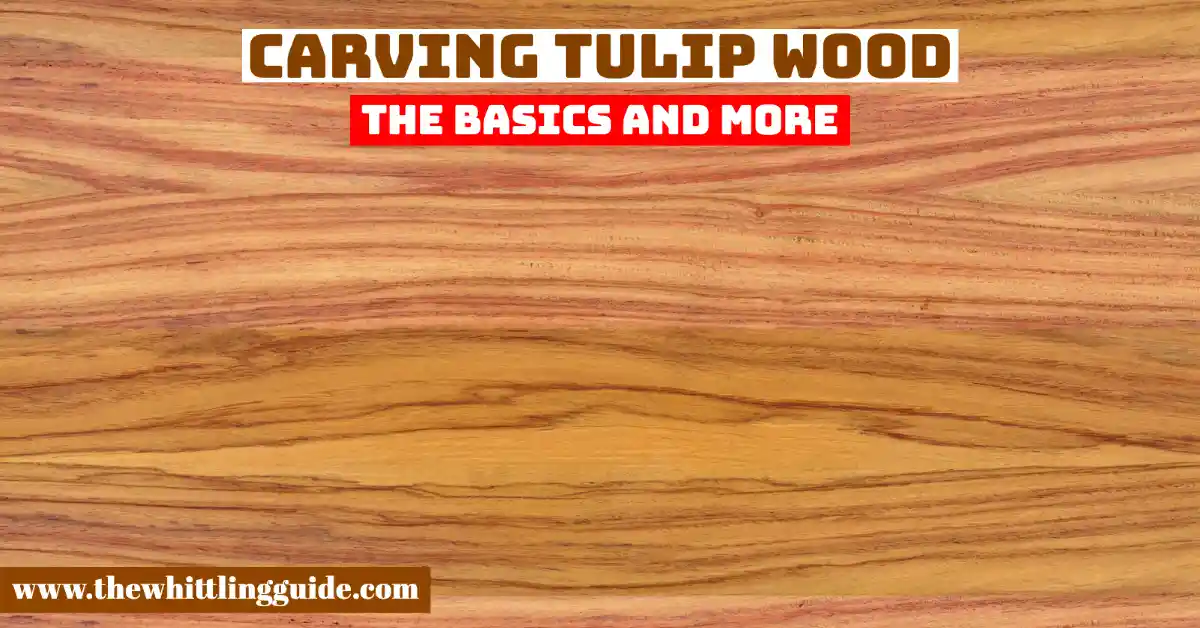

Tulipwood is a medium-density wood with low bending. Amongst its properties is the ability to resist shock. It is stiff and comes with compression values. It is strong for its weight and makes laminated beams and structures. Tulip Wood comes with creamy, white, and sometimes streaked sapwood. The heartwood varies from pale yellowish brown to olive green.

The heartwood’s green color darkens when UV light is exposed and turns brown. The Tulipwood has a medium to fine texture and comes with a straight grain. Tulipwood comes in variations depending on the growing regions. It is versatile since it makes multiple items.

The Tulip tree takes the shape of the European poplar. Tulipwood works for construction, furniture, interior joinery, kitchen cabinets, doors, paneling, moldings, edged-glued panels, turning, and carving. The timber is versatile and easy to machine, drawing without much affecting.

The wood comes with good dimensional stability and splits when nailed. It takes and holds paint, enamel, and stain well. Tulipwood is always available and affordable, making it ideal for beginners. Do not kind the burls and swirls in the grain since they are not defects. It comes with limited purplish-blue mineral color.

Tulipwood belongs to the hardwood family and is durable. The texture is quite impressive. The tree has a height of 37m and a diameter of 2m or more. The timber is wide, soft, and light in weight and 510 kg/m³ when dried. It holds hard enamel finishes excellently. It would be worth seeing How to carve Applewood.

Which tools to use for tulip carving

- Gouges.

- Chisels.

- Carving knife.

Tulipwood types

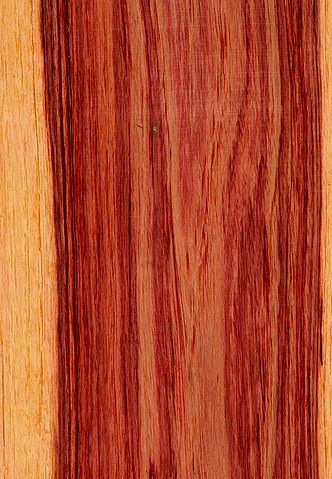

Brazilian

Brazilian Tulipwood is a high-quality, dense wood. It comes with a lovely figure. It is ideal for inlays in furniture and small carved items. What separates it from the rest of Tulipwood is that it comes only in small sizes. It is popular in luxury furniture, and it is subject to fashion. Brazilian Tulipwood comes from a species of Dalbergia.

American Tulipwood

American Tulipwood is a cheap, soft, pale wood from the tuliptree. Canary whitewood and canary wood are alternatives for American Tulipwood.

Australian Tulipwood

Australian Tulipwood comes from tulipwood trees. The popular name is Harpullia, prized for its dark-colored timber. Harpullia pendula are street trees along the east coast of Australia.

Tips for Carving Tulipwood

- Ensure that your cutting tools are sharp since they tear if the cutting edges are less than optimal.

- Use a slow feed speed to avoid tearing. That means drilling and boring at slower RPM speeds than you would use for other hardwoods.

- Since Tulipwood is soft, it needs to be sanded with finer grits of sandpaper since more coarse grits leave sanding marks that need removal. Start with 80-grit, then move to 150-, 220-, 300-, and finally, 400-grit sandpapers bring good results.

- Tulip takes stain in a blotchy manner. That means all surfaces should be prepared properly with coats of a pre-stain wood conditioner. That allows the wood stain to be absorbed evenly and makes the grain pop up.

- Gel stains work better than penetrating wood stains. Water-based stains sometimes cause fuzziness on the wood surface. Run light sanding before applying a varnish.

- When using tulipwood to simulate finer hardwoods, remember that it is tricky since the grain of the two kinds of wood is similar. However, the trained eye spots the differences. When attempting to mimic another wood, such as maple, use a wood free of gray or greenish sections. If it has grain, work with it. It tends to have large sections that are of a darker color than creamy white.

- Test your stain for the right color on scrap cutoffs of the same Tulip boards you used in the project.

- Apply a couple of coats of pre-stain wood conditioner to the cutoffs before applying your test stains.

- Fine-tuning your stain color on scrap stock is better than staining your entire project with the wrong color. It gives you chances to make amendments and multiple chances of trials.

- If you want to use it for outdoor woodworking plans, apply a new coat of paint regularly. That depends on the project and the location of the finished piece.

Is Tulipwood good for carving?

Tulip Wood is prone to cracking, so you should avoid carving while green. You can use the fallen limbs to carve walking sticks with good results. The availability of the wood allows you to practice more till you have mastered your skills.

Tulipwood lacks the density of other woods. As much as you should start working on the wood when dry, it gets as hard as a rock. It works on furniture companies, pallet mills, and backyard sawmill operations. It also makes boxes and cabinets. Do not limit yourself. Tulipwood carves with a glide. It is strong and paints well.

Is tulip tree wood good for anything?

Tulip is a wood species used in multiple woodworking projects, and it is found in many furniture projects, toys, and wood turnings because it is affordable. Workability is one of its features in the woodwork sector, and it takes nails, screws, and glue well.

It is compatible with paint as a finish and simulates finer woods. Follow the correct steps in the finishing process. Tulip is also for industrial purposes, such as finer plywood’s core layer. Tulip takes paint well, making it ideal for building woodworking projects that need painting. It is resistant to decay, and when sanded, primed, and painted properly, it holds up well to normal wear and tears for interior projects.

Is tulip tree hard or softwood?

Tulip is hardwood, but they are not very hard, which means it is soft hardwood. Since it is an angiosperm, it automatically belongs to hardwood. The gymnosperms include conifers such as pines and cedars, and these are softwoods.

Although it is technically a hardwood, Tulip is one of the softest commercially used woods on the market. It cuts easily and has uniform grain patterns. However, it does not finish very well. Sometimes it is used for cabinet-grade woodworking or on items where a natural wood appearance matters.

It is readily available at lumber stores and home improvement centers. It remains one of the least expensive woods you can buy. It is a DIY-friendly wood for home projects such as shelves and simple trim since it paints and cuts easily.

Is tulip wood expensive?

Tulipwood can be expensive, but it is also a good choice for beginners. Carving with tulipwood is a good way to learn the basics of carving. Compared to the price of some other woods, tulipwood is relatively affordable.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024