Ash wood carving

As one of the most abundant materials in the world, ash wood offers some excellent properties for carving. Originally from New England, it has recently gained popularity. It is robust, sturdy, and resistant to rot, making it an ideal material for projects that require longevity. There is no one-size-fits-all recipe for carving with ash wood. Each piece of ash wood is unique and has its strengths and weaknesses. Keep a few guidelines in mind if you use this wood for your projects. Let us look at some “ashy” details.

Properties of ash wood

Ash Wood is similar to oak wood in both grain structure and hardness. It is more resistant to rot, and that makes it last longer. Ashwood is hard, like most hardwoods and if you get your tool edge in the grain, it sometimes splinters or splits. Its hardness lies somewhere between red oak wood and white oak wood. However, the grain is neat.

If you power sand it, it produces dust that smells like oatmeal and stains well. However, it does not paint like a hoot. It has an open grain structure that is sometimes hard to fill enough to get it smooth.

Exercise extreme caution while carving. When using chisels, take your mallet, knives, and small bites so that you know how it turns out with different tools. The wood requires more force, although you will be increasing the risk of slippage and injury. Ashwood is harder than Basswood, and sharp tools become more critical in reducing necessary force.

It dries fast, and carving green wood gives you an item that shrinks quickly. Dry wood accommodates detailed carvings. However, greenwood is a little easier to wood carve with chisels. It carves like Oakwood except that it has more minerals in it. Milling it or felling the trees with a chainsaw creates sparks multiple times, dulling your tools quickly. You should also see How to carve Balsa Wood

Both green and dry carving and turning produce dust that irritates the eyes. Ashwood tends to split, chip, and tear out. That makes it last for a short period. It takes fine details decently. When carved green, it takes fine details. When dry, it breaks apart.

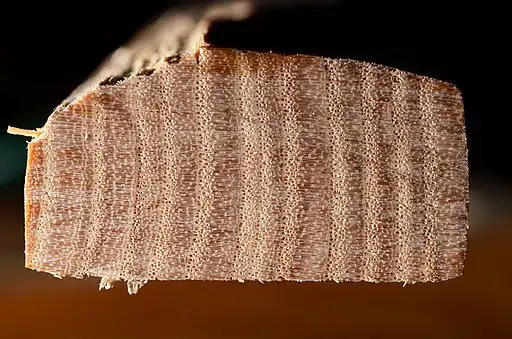

Sanding brings a smooth surface to your carving, but it is tricky because of the widely spaced summer/winter growth rings that are soft and hard. So when you sand, you will be sanding away the soft part leaving the harder rings raised. That leaves a starved horse effect to the wood, and that leaves the surface rough and uneven. You are allowed to toss your work into a bucket of water overnight to keep it wet until you start carving.

Is ashwood a good wood for carving

Carving ash wood as green wood is easier than dry wood. The moisture content should be less than 50%. It remains strong, which makes it a good choice for tool handles. These characteristics also work against it as green whittling wood, and it is not a forgiving wood and not ideal for beginners.

It comes with clearly identifiable growth rings. That makes it possible to see the open ends of larger xylem vessels in some cut surfaces. What makes it a popular wood is that it is a ring-porous wood, and it has large water-carrying vessels that are not distributed evenly through the summer growth ring.

Ash makes a high-quality, durable surface. That makes it ideal for a wooden item such as a spatula. Ash makes tool handles and canoe paddles. Ash does not respond well to storage underwater. An unattractive greying penetrates the surface, which is a problem in storing ash blanks.

Is ash wood soft

Ash is hardwood. Ashwood from the deciduous species of the tree is hard. It is even harder than oak but less resistant to moisture. The wood from this tree is so hard that it makes baseball bats. On the Janka hardness, it scores 1320. That is harder than oak, beech, or heart pine. Ashwood’s durability makes it ideal for flooring.

What are the disadvantages of ash wood?

Ashwood is not for every purpose. It is difficult to work and not durable enough for some projects. Even the best ash wood comes with its shortcomings. Learning the cons of ash lumber helps you choose the perfect wood for your projects.

Although ash stains and sands well, the wood has open pores to be filled for an even and smooth finish. Sand with care since improper sanding causes scratching across the grain. The wood’s long fiber causes splintering when turned on a lathe. Ashwood sometimes dull tools with softer edges, and that is why harder ash woods require pre-drilling before nailing. That is to avoid the risk of splintering.

Ash is a non-durable, perishable wood, and that is why it is not ideal for boat building. When damp or in contact with the ground, it is prone to rotting, attacked by beetles and fungus. However, the heartwood may resist treatments to preserve it since it is less porous than the surrounding sapwood.

According to the Janka hardness scale, Ashwood has a Janka hardness rating of 1320. That makes it harder than other species, such as red oak. However, it is softer than exotic woods like the Australian cypress, zebrawood, and ebony. It is also softer than hickory. This hardness rating makes ashwood inappropriate for uses where hardness is a concern.

Which is harder, ash wood or maple?

Maple is a harder wood than ash. Maple’s density lies in its grain structure, the most visually noticeable detail between the two kinds of wood, and Maple comes with a tighter grain structure with little space between each grain compared to ash.

Maple and ash are different types of trees. Although both are types of hardwoods, maple is a white hardwood with a tight and even grain. It comes in two variations: hard and soft maple wood. Ash is a hardwood with multiple uses. It is harder than oak but softer than maple. Ash has a creamy white to light brown color.

Is ash good for making furniture?

Ash Wood comes with straight grain and a beige-to-light-brown hue, which makes it attractive for fine furniture. Its durability makes long-lasting furniture. However, that does not compromise its weight; it remains lightweight and absorbs wood stains very well.

Versatility is one of ash wood’s strengths that makes the production of durable timber for furniture projects possible. It also takes stains and other finishing products well.

How to prepare ash wood for carving

- Cut the wood into the sizes that match your carving. For smaller sizes, like chess pieces, cut smaller sizes. When working with branches, cut horizontally across the grain and save the vertical cuts for later use.

- Remove the bark if possible. Remove the loose bark to allow the moisture to escape through the sides of the wood.

- Coat the end of the wood with paraffin or shellac. Paraffin has to be heated to melt.

- Store the wood in a sheltered area to avoid contact with the rain. You should not tightly stack the wood together, and I encourage you to allow good airflow between the pieces.

- Dry the wood for a minimum dry time of six weeks. Avoid drying wood during winter because the moisture is frozen in the wood if the temperatures drop below freezing.

Finish ideas for ash wood

You have numerous options for treating ash wood: Varnish, wax, lacquer, and oil. Each finish requires special care. Keep your ashwood furniture in a dry place and dust it frequently. Commercial cleaners and polishes will damage the surface or make it sticky. Therefore, stay away from both.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024