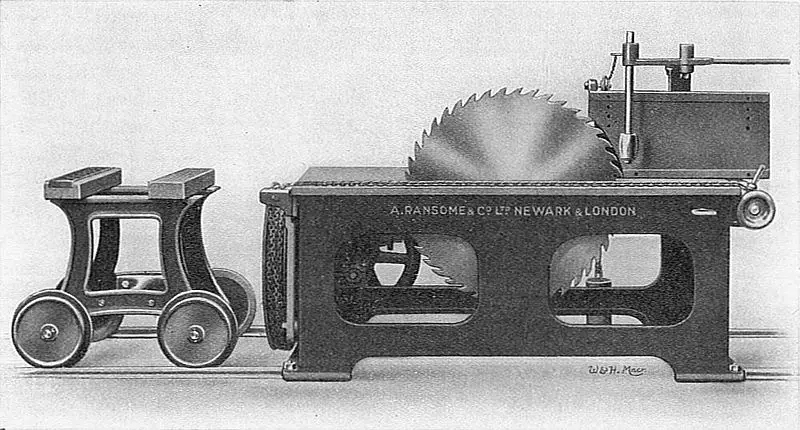

The choice between bench saw vs table saw isn’t always straightforward. Table saws have mostly replaced bench saws. As shown in the picture below, bench saws have been around for some time. If you are in the market for a new saw, you need to know what type of saw is right for you and the projects you are planning. Bench and table saws are two different types of saws, but both have their own unique uses. The table saw is often used for cutting long pieces of wood, while the bench saw is used for finer details. In my experience, the height difference is an important differentiator. It is important to have the right tool for your job.

What is a bench saw

A bench saw is a machine that cuts long pieces of wood into smaller pieces. It has a sawing technology that lightens heavy loads and gives accurate cuts and secure working conditions.

It is ideal for DIY woodworkers looking forward to producing lengthwise cut boards. It has a circular saw that is underneath the work table. The work table is sturdy, and that makes the bench saw stable.

The open design allows you to control the depth of wood you want to cut. It cuts both long and shortboards. That is made possible by adjusting the saw blade’s angle. Position the blade up or down depending on the depth of the wood you would like to cut.

The guides accommodate multiple angles the user might think of applying. The sturdy frame makes sure that the chances of accidents are slim. When choosing a bench saw, you must consider accuracy, portability, and motor system.

If you must carry it to and from work, you must look for a portable bench saw. Stationary saws are perfect for workshops. The fence system determines the accuracy of the cuts of large stocks of wood pieces. It has to extend from the table. A combination of a fence and a rail makes an excellent fencing system.

Parts, features, and functions of a Bench saw

Rip fence

The Excel bench saw has a lever lock rip fence for accurate straight cuts. The rip fence is a guide that stays parallel to the saw’s blade. It is movable, and it measures the board you are cutting. The hold-down is the guide that keeps the board on the table.

Motor

A motor makes the bench saw sturdy. Small bench saws have motors attached to a small bracket to the side of the table. That makes the raising and lowering of the blade. Big bench saws have guide rods or tracks that manage the blade’s position. Vibrations are low since the saw blade is running faster.

Stand

The stand carries accessories. They stay closer to the user so that less time is spent on a project. Your materials are in order, and your accessories are easy to reach.

Bevel and miter cutting

Place the saw guard and anti-kickback devices right before you start cutting. The miter guard is on the opposite side from which the blade tilts. That increases the distance of the hands from the saw blade. The miter head holds down clamps as you hold the stock in place.

Rip cuts

Alignment and locking the rip fence are procedures you must observe before cutting your material. The rip fence is set for the desired width of cut using a scale on the front rail. The board has to behold against the fence and the table. Supporting longboards is essential, and the use of a push stick.

Uses of a bench saw

- Crosscuts.

- Rip cuts.

- Mitre cuts.

- Bevel cuts.

Advantages

- Fast.

- Accurate.

- Easy cuts.

- Versatile.

- Powerful motor.

- Efficient.

Disadvantages

- It makes noise

- It vibrates

Expert Tips

- Avoid accidents at all cost

- Put on eye protection all the times

- Use a scrap of wood to push the board

- Keep your fingers away from the blade

- Keep the blade low when not in use

Table saw

A table saw withstands longer and wider materials. It is more significant and ideal for materials that require longer cuts. It has onboard accessory storage that keeps extra blades, the miter gauge, and the rip fence. There are table saws that come with additional shelf space.

The solid base makes the tool sturdy as it stays in place. That brings convenience to the user when you need to replace your blade. There are also industrial table saws with large surfaces and workbench table saws that are ideal for DIY enthusiasts.

You connect your tool to a dust management system that keeps you healthy from diseases caused by inhaling dust saws. The blade on a table saw is fixed. The height is adjustable as you raise it lower or higher, depending on the thickness of the wood you are working on.

The blade is stationary. For accuracy, the blade guard and rails guide the material. There are four types of table saws. These are the bench, contractor, cabinet, and hybrid table saw. The contractor and the cabinet table saws are portable for household activities.

The cabinet table saw combines the two, and the hybrid table saw is a heavy-duty table saw.

Parts, features, and functions of a Table saw

Motor

The Dewalt 10inch table saw has a 15A high torque motor powerful enough to cut through treated hardwoods. The horsepower determines the cutting power. Light bench saws are compatible with the 3/4hp to 1.5hp. They cut up to 5/8 inch thick material. The cabinet table saw uses the 5hp motor.

Blade size

When manufacturers are naming a table saw, they are after the blade size. Table saws come with circular blades, and the 10inch is the standard blade. The blade is adjustable depending on the material you are working on. The Dewalt 10inch table saw uses a 10inch tooth carbide blade that makes fast and smooth cuts.

Cutting depth

The type of cut depends on the width of the blade. Shallow cuts attract wider blades. A 10inch blade can make a deep cut of up to 3.5inches. A 12inch table saw makes a deep cut of up to 4inches.

Fence options

The fence is the adjustable guide of the saw. It makes your material stay in place. The T-square is the standard fence that is ideal for common cuts. Specialty fences have a micro-adjust feature. The Vega U26 Table saw it has micro-adjustment table support. You are allowed to fine-tune the measurements of the cut.

Rip capacity

I recommend a table saw that rips materials with accuracy. However, it also depends on the ideal materials you will be working on. The rip capacity ranges from 18iches for entry-level saws to 60inches for high-end saws.

Uses of a table saw

- Crosscuts

- Ripping cuts

- Dado cuts

- Bevel cuts

- Fine rabbets and Grooves cuts

- Kerf cutting

Advantages of a table saw

- Table saws are available on a variety of price tags. They range from 250 to 5,000 depending on your budget and working conditions.

- Onboard accessory storage

- Adjustable blades

- Accurate

- Effective dust management system

- Specific table saws for different locations

Disadvantages of a table saw

- High noise level

- A bit unstable

Expert Tips

- Use the right blade

- Keep the saw clean and the environment

- Use a dado set for rabbets and groves cuts

- A miter gauge and fence are for precise cuts

- Every amount requires a supplementary tool

Bench Saw vs Table Saw Cost

Table saws are on a variety of price tags. They range from 250 to 5,000 depending on your budget and working conditions. Bench saws range from 30 to 600. That makes them more affordable than table saws.

Verdict

If you know why you need a saw, find the best product. For professional use, I recommend a table saw. It is suitable for more extensive materials than the table saw. However, for both saws, there is a range of saws for heavy work and those for small DIY projects.

A portable bench and a small table saw are ideal for home use. Stationary saws are for workshops. Since a table and bench saw are similar, you must compare your needs to each model to take your best pick. Please have a look at our Track Saw vs Table Saw comparison.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024