Are you looking for the best wood lathe? Whether looking for a wood lathe to improve your woodworking skills or turn wood into works of art, you should consider a few key features. This article looks at the best features of woodturning lathes and their benefits for woodworkers. We will also go into detail about some of the options.

| Image | Name | Link |

|---|---|---|

| Mophorn 10 x 18 Inch Wood Lathe Bench | CHECK ON AMAZON |

| Delta Industrial 46-460 12-1/2-Inch Variable-Speed Midi Lathe | CHECK ON AMAZON |

| NOVA 46300 Comet II Variable Speed Mini Lathe 12-Inch x 16 1/2-Inch | CHECK ON AMAZON |

| Jet JWL-1015 Wood Working Lathe | CHECK ON AMAZON |

| RIKON Power Tools 70-105 10" x 18" 1/2 hp Mini Lathe | CHECK ON AMAZON |

A LATHE MACHINE is commonly used in metalworking, metal turning, woodturning, and glassworking. The different activities that it can perform incorporate the accompanying: sanding, cutting, knurling, penetrating, and twisting of devices that are used in making objects which have symmetry about the centerline of spinning.

The lathe machine’s most widely recognized results are crankshafts, camshafts, table legs, bowls, and candle holders. There are various types of lathe machines available in the market. I’ll come up with some well-renowned machines which are portable. These are the best at their services, simply operable and more or less affordable in the ending section of this article. But first, we should have an overall look at the lathe machine.

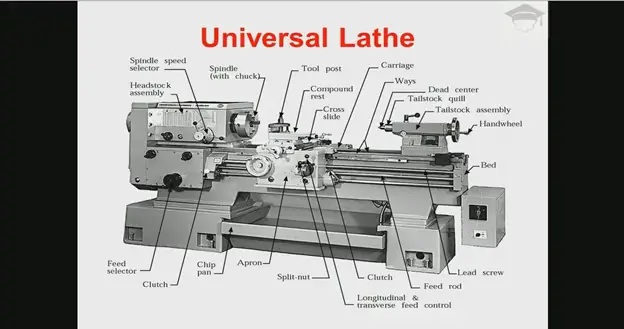

Common parts or body features of Lathe Machine:

Headstock

It is located on the left side of the lathe. It contains the chuck, the entire shaft, the throw, the gear switches, and the feed control. It is in line with the tailstock. The headstock is made of cast iron. It can be divided into three small parts.

Chunk

It is that piece of a lathe machine used to hold the workpiece. It is added to the fundamental axle of the headstock. It turns with the axle and pivots the workpiece. In the lathe machine, we, for the most part, utilize a three-jaw or four-jaw check. The three-jaw of the three-jaw hurl is made to move simultaneously, yet the jaws of the four-jaw throw move freely.

Main Spindle

This piece of the lathe machine holds a tube-shaped workpiece inside it. It is an empty shaft on which the hurl is mounted.

Feed Selector

It is used to select the direction of the feed. The feed selector is present on the headstock.

Tailstock

It is available on the right-hand side of the Lathe. It is used to give support to the workpiece. It underpins the workpiece from one end, for example, the right end.

Bed

It is the central part of the lathe. It is made of cast iron. It includes the headstock, tailstock, slide guide rails, and other parts. All parts of the lathe are cast on the bed.

Guideways

Guideways are available on the bed. As its name demonstrates, it controls the tailstock and carriage. The tailstock and carriage slide over the guideways. It is a modified V.

Carriage

The carriage is located in the center of the headstock and tailstock. It includes a cover, saddle, cross slide, and device holder. It is combined with five essential parts.

(I) Tool Post: It is used to hold the tool. It has a T-opening for holding the tool. The tool post is bound to the carriage.

(ii) Compound Rest: Set the device at the ideal plot to decrease turning and different activities.

(iii) Cross Slide: The cross slide moves the device opposite the Lathe’s hub.

(iv) Saddle: The top bit of the carriage is known as the seat. A Cross slide is mounted on the seat.

(v) Apron: The front segment of the carriage is called the saddle. It contains all the moving and control systems of the carriage.

Lead Screw

It is likewise known as a power screw. This situates at the base side of the bed, which moves the carriage naturally during the thread-cutting activities.

Feed Rod

The feed rod is a power transmission instrument used for the exact straight development of the carriage along with the longitudinal hub of the Lathe.

Chip Pan

Chip Pan is used to gather the chips created during the lathe activity. It is available at the base of the Lathe.

Hand Wheel

Hand Wheel is used for pushing the tailstock ahead or in reverse.

Types of Lathe Machine

Lathe machine is generally divided into three types.

- Engine lathe

- Turret lathe

- Special purpose lathe

How many operations can a lathe machine perform?

The different tasks that we perform on the Lathe are:

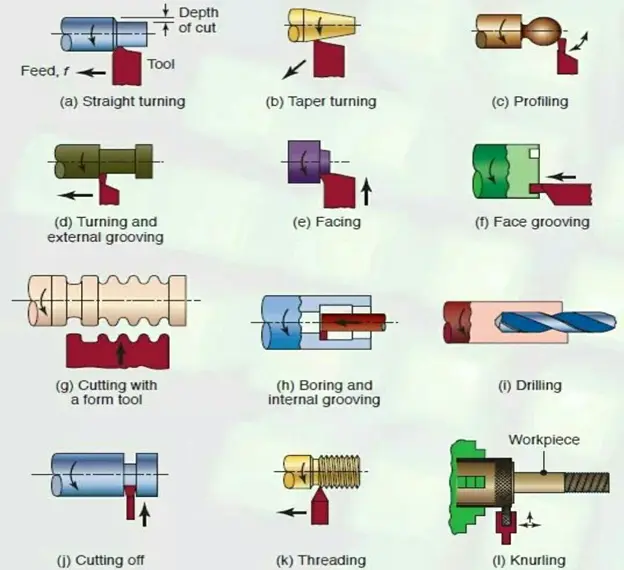

Facing

The way toward making a level surface on a lathe machine is called facing. To securely place out a facing activity, the part of the arrangement must be as close as possible to the jaws of the toss. The activity is hung on a chunk, and the tool is inserted at the right points to the bed to get level surfaces.

Turning

Tuning is when metal discharge happens from the outside of the barrel-shaped workpiece. In this procedure, a tool is sustained along with the center of the axle. Turning is the discharge of metal from the external distance across a rotating around and hollow workpiece.

Turning is used to lessen the width of the workpiece. Furthermore, step turning is an activity performed on a lathe machine where an excessive quantity of material is removed from the workpiece to get different steps of various widths.

Chamfering

It removed the burrs and sharp edges and made the dealing safe. This should be possible by a structured tool with an edge equivalent to chamfer, commonly kept at 45°.

Grooving

For the most part, the term grooving applies to forming a thin cavity of a specific depth on a part’s chamber, cone, or face.

Forming

The forming procedure is the activity or procedure where the workpiece is reshaped without including or removing material, and its mass stays the same.

Knurling

It is the way toward making spaces on the border of a workpiece. The knurling activity is done to give a superior hold to the activity. It is performed by the knurling tool. The knurling to l is firmly pressed against the activity to play out the knurling activity.

Taper Turning

The taper turning is a lathe activity for creating a funnel-shaped surface by steadily decreasing the width of a round and hollow workpiece.

Thread Cutting

Threading is an activity performed on a lathe to produce a thread using a tool whose shape corresponds to the threads. A thread is a spiral section on a round and hollow surface. Types of screw threads, terminology for screw threads, setting the lathe for threading, tool pulls, simple pull, compound pull.

Drilling

Drilling is the way of making gaps in the workpiece with the help of drilling tools. The drill is suspended from the tailstock and is driven into the workpiece by pivoting the tailstock handle. On a lathe, drilling is usually performed at the focal point of the workpiece.

Reaming

The way toward broadening the openings to exact sizes is called reaming. Reaming is constantly performed after drilling activity. The reamer is held in the tailstock to complete the reaming activity. It is like the drilling procedure.

Boring

The procedure of stock discharge from a gap in the workpiece is called boring. The cutting shaves off a slim layer of material to the exact size. Openings are exhausted by the single-point tool.

Tapping

Tapping is the way toward cutting a thread inside an opening so that a top screw or fastener can be threaded into the gap. Additionally, it is used to make threads on nuts.

Parting

It is the way toward cutting a workpiece after being machined to the required shape and size.

Treading

Threading is the way to make threads in a round and hollow position.

Undercutting

Undercutting increases the diameter measurement if made internally and decreases the distance if made externally. The measurement is made toward the end of the hole, near the graded shoulder of a round and hollow surface and the part of the arrangement package in the smear.

Eccentric Turning

It is a turning activity performed at an alternate axis on a single task process. This technique for turning is commonly used to deliver crankshafts and camshafts.

As I stated before, beginning with this discussion, I made the top 5 list of lathe machines, which are basically for woodturning. You can choose from any of these variations as per your requirements. This product’s durability is well-praised.

Mophorn 10 x 18 Inch Wood Lathe Bench

Mophorn 10 x 18 Inch Wood Lathe Bench Top Heavy-Duty Wood Lathe Stepless Speed Regulation Digital Display doesn’t come with any tools, just a little wrench to set it up. It would be best if you bought wood carving tools separately. You can do many things, to turn bowls, wood pens, rings, and many things! You’ll need a chuck. It does have a one-year warranty.

2. Delta Industrial 46-460 12-1/2-Inch Variable-Speed Midi Lathe

2. Delta Industrial 46-460 12-1/2-Inch Variable-Speed Midi Lathe

Delta Industrial 46-460 12-1/2-Inch Variable-Speed Midi Lathe is made for woodworking. This 97-pound g ey color machine includes a ball-bearing live

NOVA 46300 Comet II Variable Speed Mini Lathe 12-Inch x 16 1/2-Inch

3. NOVA 46300 Comet II Variable Speed Mini Lathe 12-Inch x 16 1/2-Inch

The NOVA Comet I Midi Lathe is ideal for a broad scope of carpentry ventures. Versatile, space-sparing – yet conveys the limit and the rugged dependability of bigger lathes. With NOVA’s great Versaturn Accessories, you can change your NOVA Comet II Midi Lathe into overall woodturning and carpentry machine.

Variable Speed Midi Lathe is the most adaptable and imaginative little Lathe available today. The red and silver color old model NOVA 46300 Comet II 12 Inch x 16 1/2 Inch dimension is 33 x 9 x 18 inches. It’s at home as the essential or optional Lathe in a multi-utilitarian workshop, or incredible for the individuals who travel a ton for their leisure activity or educate/show often.

Also, it is backed by a full replacement 1-year warranty on motor and electronics and a further 2-Year limited warranty on all parts, excluding motor, electronics, and consumables, for a total of 2-Years limited warranty.

Jet JWL-1015 Wood Working Lathe

4. Jet JWL-1015 Wood Working Lathe

The new JET 1015 woodworking lathe, measuring 35 x 18.1 x 14.6 inches, is the perfect decision for the woodturning student looking for a moderate, easy-to-understand first lathe and the avid follower or an expert looking to add a full-size, smaller-than-usual lathe to their workshop.

This rugged, smooth-running 15″ smaller than average Lathe has the power, exactness, and flexibility to turn out any number of undertakings. You can buy this product confidently at an affordable price and a 5-year warranty.

RIKON Power Tools 70-105 10″ x 18″ 1/2 hp Mini Lathe

5. RIKON Power Tools 70-105 10″ x 18″ 1/2 hp Mini Lathe

RIKON Power Tools 70-105 10″ x 18″ 1/2 hp Mini Lathe is planned explicitly for pen turners who need a durable, devoted machine for their specialty. The product dimension is 35.5 x 10.5 x 14.8 inches. This downsized, fundamentally smaller than expected Lathe is developed of cast iron, so vibration isn’t a factor, unlike different lathes made of aluminum.

5 Speed reaches spread the bases for drilling barrel openings, roughing out pen billets, going to shape, and wrapping up. The lathe incorporates a live focus, tool rest, knockout bar, and wrenches. With this product, you can get these components such as Lathe, 6″ tool rest, Live center, spur center, Rubber Feet, Manual, Wrenches, and five years warranty.

Conclusion:

Individual structures may improve or be more terrible than plans, but asking about the advantages and disadvantages without specifying is nonsense. Machines don’t have points, pros, or cons in that capacity. A lathe completes a specific task. It doesn’t do things it wasn’t intended for.

It uses control. So, various kind of lathe machine does various jobs. But you’ll face some aftermath, like – The lathe takes up space in your shop. You will face the consequences like – The Lathe occupying a room in your shop.

It requires tooling and accessories, which themselves must be put away quickly. When a lathe is dirty, it makes chips, and chips get into everything, from beards and hairs to shoe soles, pushing you into difficulty when you track them in the house.

A “swarf,” a blend of greasy oil dirt alongside crushing buildup from sandpaper, file residue, and simply ordinary waste matter that costs everything. Those difficulties will turn to ease if you can skillfully handle everything. It would help if you stocked cutting liquids, pressurized lube, and other chemical mixtures, and the more you have a lathe, the more they will load up.

To conclude, we can share the same thought: every piece of the machine is significant and performs a tricky purpose. The individual woodwork machine is called the turner. It entirely relies upon the expert turner to work superbly, which requests a tremendous degree of consideration.

A lathe is one of the most versatile and broadly utilized machine tools. It is regularly known as the mother of all other machine tools. Since this is a powerful tool used in the machining procedure, this has turned into an essential piece of making an innovative product. You can never consider producing metals and different materials without a lathe machine.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024