Can you use a Dremel bit on a drill?

You can use Dremel bits in a drill if the rotary-tool head does not require high speeds. Looking at the small diameters that come with small diameters, Dremel bits need high speed to work perfectly.

Using the Dremel bits on hard materials will get the high torque shattered. Dremel bits physically fit in a drill, but it has drawbacks. Dremel tools run at high speed, and paring the rotary tool slows down the process.

The project took longer than expected, resulting in a poor-quality finish. The Dremel bit should not be used in a drill for larger projects since it compromises the quality of the material. There is a high risk of injuries or damage to your material.

When the tool bits do not pair enough with the drill, it slows down the process. The Dremel bit is ideal for smaller tasks and DIY projects. Using it on soft material gives better results. Apply less pressure to reduce the chances of breaking. Safety precautions should be observed, and read the instructions carefully.

Can you use rotary tools on a drill?

You can, as long as your tool head does not require high speeds. A drill press has much higher torque than a Dremel but much lower RPMs. This means you can use a drill press to drive a rotary tool, not the other way around. The best way to use a rotary tool with a drill press is to set the drill press to a lower speed and apply light pressure. This will prevent the rotating tool from overloading the drill press motor and burning it out.

Can you use Dremel bits in other rotary tools?

Yes, Dremel brand bits will work in other rotary tools. Tools of other brands are interchangeable with them. The Dremel company makes several rotary tools, each designed for different tasks. The Dremel 3000 is the most popular and suitable for general use. Dremel bits are circular saw blades that can be used to cut other materials. These include wood, metal, plastic and

Is a rotary tool the same as a drill?

A Dremel and a drill are both hardware power tools. They both work in almost the same way. That is why they are rotary tools; they rotate fast to do some hardware work. But their mechanisms can be quite different. A Dremel is a speed-based tool, while a drill is a power-based tool.

What are rubber Dremel bits used for?

These rubber polishers help to smooth out the roughness of metals on platinum, gold, and Argentium silver. They are ideal for cleaning and defining grooves on non-ferrous metals, stones, stainless steel, marble, and ceramics. They are for finishing and polishing all ferrous metals and removing small burrs and scratch marks. They are also effective on many stones and ceramics.

Can you put a router bit on a drill?

A drill bores holes and is designed for downward pressure, while a router shapes edges and cuts grooves. This difference, among others, makes a drill unsuitable for use with a router bit. It handles significant sideways pressure.

You can use a straight router bit for drilling because it works on multiple projects and materials. As long as it is a plunge bit, tightly clamp the workpiece. That works if you are not particular about appearance, it will work.

What are diamond Dremel bits used for?

Diamond drill bits are suitable for drilling holes in hard materials such as glass, stone, ceramics, bone, shells, pottery, and porcelain. They drill holes in flat, contoured surfaces such as glass or ceramic walls. It is also used to enlarge existing holes. The diamond Dremel drills range from 0.5 mm to 1.5 mm in diameter. Different types of diamond drill bits are available in the market, such as flat head, round head, and cone drill bits.

When drilling a hole with a diamond Dremel bit, always start at a slow speed and gradually increase it as you progress. The drill bit can overheat and break if you drill at high speed. It is also important to lubricate the drill bit with water to cool it down and prevent breakage.

When choosing a diamond drill bit, always consider the type of material you will be drilling, the size of the hole, and the speed at which you will be drilling. Choosing the wrong drill bit can damage the material being drilled and cause the hole to be too large or too small.

What are Dremel bits made of?

These are sharpening stones made of silicon carbide or aluminum oxide. They are cylindrical and work well for grinding profiles and holes. The bits come in assorted shapes and sizes, including a ball, cone, rounded cylinder, flat top cylinder, and tapered.

Are drill bits universal?

No, not all bits are compatible with all types of drills. Different types of drills require various bits, and even within a particular type of drill, there may be incompatibilities between brands or models. It’s essential to check your drill’s owner’s manual to see which bits are compatible. However, most standard twist drills will work with most standard drill bits.

Are drill bits standard?

No, not all drill bits fit in all drills. A 3/8 inch-sized drill will accept up to 3/8inches drill bit shafts. ½inches sized drills will accept up to ½inches drill bit shafts as well as 3/8inches sized bits. Universal drill bits exist to drill holes in multiple materials. That is from wood to concrete. However, some may not be suitable for drilling into more fragile materials such as ceramics and glass

Can I use screwdriver bits in a drill?

Yes. Put the screwdriver bit into the chuck. The chuck is the part at the front of the drill that holds the bit. Tighten with the chuck key so that the drill holds the bit. Do not overtighten the drill bit. Make sure it is entirely secure and will not loosen as you work with the screw.

Can you use DeWalt drill bits with Black and Decker drill?

Yes. It does not matter what brand of tool you have. What matters is the size of the drill bit, even if it is 3/8 or ½inches. They are all interchangeable as long as they are in the size range and type. Black and Decker and DeWalt are the same company. Drill bits and screwdriver bits are standard.

Dremel bits physically fit in a drill, but it has drawbacks. Dremel tools run at high speed, and paring the rotary tool slows down the process. Using the Dremel bits on hard materials will get the increased torque shattered.

There is a high risk of injuries or damage to your material. The project took longer than expected, resulting in a poor-quality finish. The Dremel bit should not be used in a drill for more significant projects since it compromises the quality of the material.

The process becomes slow when the tool bits do not pair enough with the drill. The Dremel bit is ideal for smaller tasks and DIY projects, and using it on soft material gives better results. Apply less pressure to reduce the chances of breaking. Safety precautions should be observed, and read the instructions carefully.

You can use drill bits in a Dremel

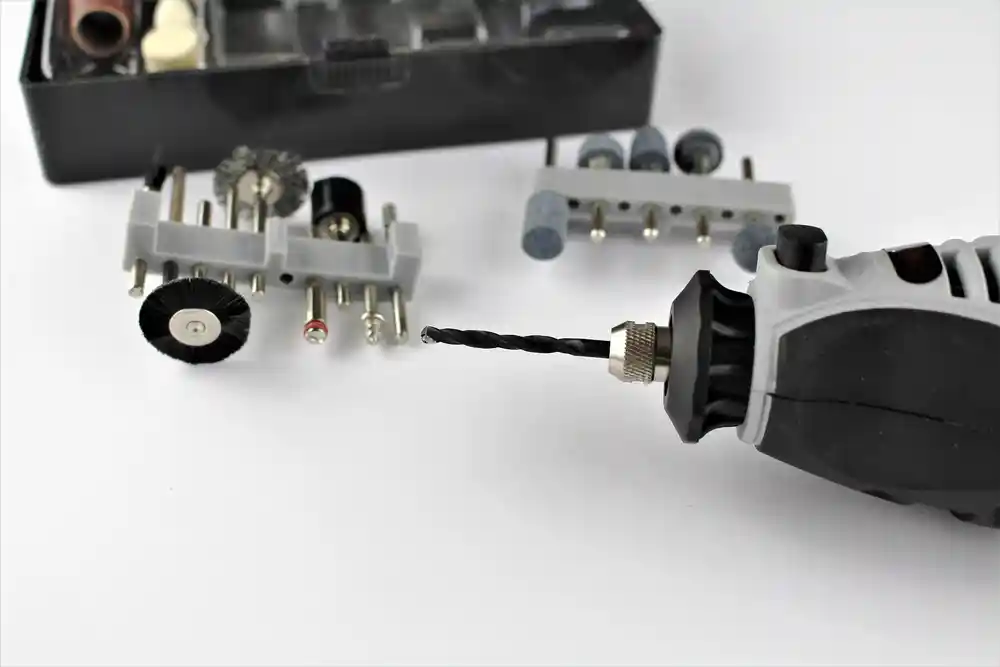

You can use drill bits in a Dremel, and Dremel is a powerful tool that works with standard bits. Dremel gives collets that hold bits in a Dremel rotary tool. It is smaller and opens wider or closes tighter with regular bits. When you choose to use a bit out of the size range that the collet accepts, use a 4486 Dremel chuck. They have shank sizes ranging from 1/32 to 1/8inch.

How to use drill bits on a Dremel

- Press that shaft lock button and rotate underneath the housing cap on the end of the tool. When the lock engages, rotate the shaft further.

- Twist the collet nut counterclockwise using a collet wrench.

- Loosen and remove the collet nut.

- Tighten the chuck onto the shank using your hand until it sets firmly onto the tool.

- Twist the chuck and insert the drill bit.

- Set the Dremel’s Lo and Hi switch to match the job you are running.

Differences Between a Dremel and a Regular Drill

Speeds

Dremel has higher speeds than a drill, although the drill has more torque. High speed allows the Dremel tool to cut the material without catching on to the material. Standard drills have a maximum of 2,200rpm, whereas a rotary tool runs at 20,000 to 30,000rpm. That makes Dremel faster while using less pressure.

Easy of use

Dremel is light and easy to use, and that makes it user-friendly. That makes it easy to maneuver in tight and small spaces, making it ideal for carving and engraving. The handheld tool is comfortable to hold for a period.

Using the flex shaft attachment yields better results. Small workpieces and confined spaces are made more accessible. The Dremel tool does not vibrate, which gives room for precision and high quality, regardless of the type of material being cut.

Dremel allows for accessorizing

The Dremel tool gives you room for multiple attachments and accessories, speeding up your projects. Drill bits are mounted on sized shanks, and the Dremel is for different applications.

A combination of Dremel’s accessories and high speed yields better results.

Speed adjustment allows you to match your speed with the perfect material. You work at the proper speed that you are comfortable with.

Purpose

Dremels are multi-functional tools compared to drills for drilling holes and driving screws, and Dremels are for sanding, grinding, engraving, routing, and many more. As much as the Dremel performs multiple tasks, it does not drill and drive screws, and the Dremel tool works on multiple materials, such as wood, glass, metal, and plastic.

Advantages of Dremel over a Drill

- Dremel has high speeds that allow it to cover a large load quickly. In contrast with Dremel, the drill does not rotate as fast as the Dremel. The drill is easy to keep under control.

- Dremel is lighter and smaller than a drill. That makes it easy to maneuver in tight and intricate spaces.

- A drill is not meant for a lateral load but rather to go straight in and out. Lateral loads destroy the bearing of your drill since it is for end-on loads. On the other hand, the Dremel cuts sideways. Rotary tool bits work perpendicular, at 90 degrees or to the direction of the bit’s shank.

- A drill drills holes and drives screws, whereas the Dremel performs multiple tasks. Such as cutting, engraving, carving, and sanding.

- Multiple-bit types work with the Dremel tool. The standard bit is the screwdriver bit. There are countless bit types and accessories that cover multiple tasks. These include carving, engraving, grinding, routing, cutting, sanding, polishing, and drilling. Carving bits are high-speed cutters, and engraving bits are engraving cutters. Cutting bits have carbide cutting and diamond wheels for the task. Drills work with a special attachment, and these include sanding bits. Drill bits are the standard bits for the tool. Each bit for Dremel fits the 1/8inch collet, which is the standard. There are optional collets sold separately. In each model, the shank sizes are small. They even fit a drill chuck, allowing one tool to complete several tasks simultaneously.

- There are chances of sideways working, such as cutting, sanding, and polishing. These are necessary and do not require specially designed attachments.

Disadvantages

The Dremel bit can be slower.

The drill has a lower rpm, and the type of finish you could get on a Dremel bit might be low quality compared to the one you could use on a drill. Higher is for specific applications such as sanding. If you go slow again, you could lose the high quality of the tool.

You will not remove the exact amount of material you want to get rid of, opening up imperfections and defects you cannot remove.

Dremel bits can break easily. Cutting may be messy, and multiple cuts are required.

Although Dremel bits have high speed, they come with low torque. Torque refers to the turning force applied when running the rotary tool, and drills have a lower rim but a high torque.

Using Dremel bits is dangerous. Dremel bits are brittle and affordable. Tightening the screw on top of the bit holder tighter causes the cutting disc to snap. In this case, bits easily break under the load of the drill.

Also, see our posts: How to cut plexiglass with Dremel & What can you do with a Dremel?

Can you use a Dremel as a screwdriver?

Buying a screwdriver when you have a Dremel tool is not necessary. However, you can still use it since you can use it if you have it already. Due to its automatic collet lock, users can turn the tool like a manual screwdriver if hand-tightening is needed. The only downside is that Dremels spin too fast to be used as a screwdriver and do not have enough torque.

Can I use any bits on my drill?

Different drill bits are for any branded machine that provides the same shank size and diameter. Not all will work well in all materials. Drill bits without a hex-shanked bit holder cannot be used in an impact driver. However, hex-shanked bits are for regular drill drivers.

Are power drill bits interchangeable?

Yes, you do not have to own a separate drill bit to match each type of material you intend to drill into.

How do I know what drill bit to use?

The diameter of the hole you drill should be slightly smaller than the diameter of the screw. For instance, if you use a 3.5 mm screw, use a drill bit with a diameter of 3 mm. If using wall anchors and screws, the drill bit and anchors should have the same diameter.

Can you use DeWalt drill bits with a Black and Decker drill?

Yes. It does not matter what brand of tool you have. What matters is the size of the drill bit, even if it is 3/8 or ½inches. They are all interchangeable as long as they are in the size range and type. Black and Decker and DeWalt are the same company. Drill bits and screwdriver bits are standard.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024