In my search for the best Myford lathe, I started with the Myford ML7. I landed on the Myford ML7 vs Super 7 comparison. Using and researching both versions for a while makes a difference in the debate. You should consider lathes: speed, motors, headstock bearings, tailstocks, saddles, drive system, construction and weight. I recommend matching these features with your needs. A detailed comparison follows in this article.

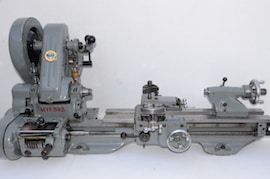

Overview of the Myford Ml7

The Myford ml7 is a compact lathe with a built-in motor, fully guarded belts, and change wheels. It has a motor drive guard and the Vee rope headstock guard for accessibility through sliding. The wick-feed lubricators keep the lathe machine lubricated. That prevents friction as you operate the lathe. It works for hand in glove with the oil reservoir that keeps your oil. The ball-type oilers are on different parts of the lathe machine, and it does not run out of lubrication.

The hollow spindle is high tensile steel that is durable. The tumbler reverse lever is in three positions. That is, the forward, reverse and neutral positions. It is tipped with plastic knobs and does not hurt the user. The wheel guard protects your wheels are enclosed. If you want to check or change the wheel, you release the wheel guard using two thumb nuts. The set screw is there to adjust the tension of your belt. The function of belt tension is to change speed.

You have to release the lever when you are controlling your speed. The oiling plug is for the pulley bearing. The felt wiper protects the shears. The tool clamp is universal and loaded with springs. The feed screws come with replaceable nuts. There is a large bearing surface from the extended saddle. The oil nipple with the lathe is an improved feature that the predecessors did not have. It keeps your lathe lubricated. As it distributes oil to the lathe machine, it also removes dirt.

Pros

- Durable tensile steel

- Enclosed wheels

- Controllable speed

- Large bearing surface

- Safe

Cons

- The position of the nuts that hold the studs compromises the performance

- Plain bearings

Key Features of the Myford ML7

Headstock

The headstock of the ML7 is rugged. It is bolted to the bed by four Allen screws made of high tensile. It is aligned by tongue fit into the space between the bed ways with two pusher screws. Strong bearing caps have cap- screws.

Change wheels and Screw-cutting

The Myford ML7 uses hardened steel pins and quick-release washers. The slot-head crews allow a quick change of gears. The nuts that hold the studs are at the back. That makes alterations difficult and time-consuming. The change wheels and the belts are in an aluminum cover. That protects them from wear and tear. The lathe does not make noise.

Tailstock

The tailstock has a barrel that is 1inch in diameter. It has a morse taper that allows it to run heavy-duty drilling. The barrel makes the tailstock withstand masses that come with different applications. Although the tailstock makes it challenging to reach the lever, it improved the locking mechanism.

Speed and Motor

The ML7 produces 640 rotations per minute. You increase the speed by using a bigger motor pulley. The maximum speed is 1000 rotations per minute. The increased flow of top-quality lubricant increases the performance of the lathe machine. The switching on and off of the motor against no-load damages the motor. The ML7 has a 1/3 hp motor, although the new model has a ½ hp motor.

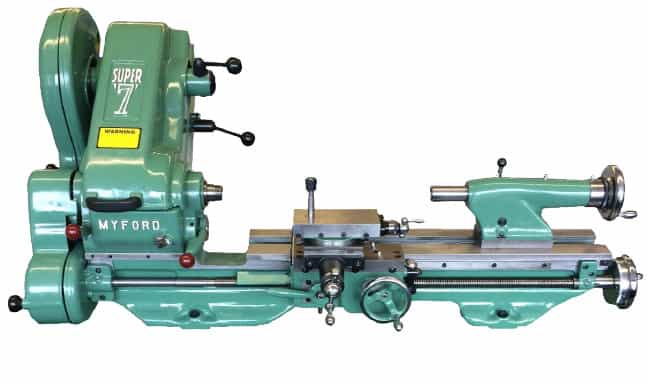

Overview of the MyFord Super 7

The MyFord Super 7 is the improved version of the ML7. It has a spindle supported by the front bearing that delivers impressive results. That is very fast for a lathe. The Super 7 has a 0.75 hp motor that allows it to pull 2,000 rotations per minute. The powerful motor makes 1,425 rotations per minute.

The headstock drive system has 16 speeds that come with a fitted clutch. However, I do not recommend the two fastest back-gear speeds. That leaves you with 14 speeds of up to 2105 rotations per minute. The countershaft pulleys and the headstock are cast iron. That is more appropriate for the parts than aluminum. The Super 7 has a fitted gearbox that generates 48 threads.

It has a headstock drip-feed oiler. It constantly supplies the lathe with lubrication. The newly-introduced clutch system is efficient for the lathe. However, it makes a rattling sound that makes noise. What is needed to avoid the sound are perfect adjustments to the clutch. The lever operates the tumble reverse and the back gear. It releases the change wheel and the belt guards. The belt guards protect the belts from wearing and tearing as they rotate. The belt guards have screws that have knobs. There is the latter version loaded with springs.

Pros

- 16 speeds

- Cast iron accessories

- New clutch system

- Headstock drip-feed oiler

- Versatile

Cons

- The original clutch tends to make noise

- A lever-operated attachment would have improved the tailstock

Key features of the MyFord Super 7

Headstock Bearings

The MyFord Super 7 has a tapered bronze bush at the ball bearings at the rear. The ball races are placed between the screwed rings. The front bearing clearance is adjusted when you move the spindle forward and backwards.

Tailstock

It has a ball-bearing thrust race and a quick-feed. It also comes with a longer barrel. The locking mechanism on the barrel is in a convenient position. That is at the front as it faces upwards. The assembly is well-built and convenient for handling the lathe. A lever-operated attachment would have brought more sensitivity when drilling. It would have been easy on small diameters.

Screw cutting gearbox

The gearbox produces 48 threads from 8 to 56 t.p.i. The double gear on the banjo gives several feeds from 0.139 inches to 0.002 inches per spindle revolution. The gearbox is built-in to the Super 7.

Speed

The Super 7 has 16 speeds in total, although I recommend 14. The other two are way faster and expose you to error. The 0.75 hp motor makes 1.425 rotations per minute. With 14 speeds, you have 27 to 2105 rotations per minute. That makes the lathe versatile.

Similarities

- They both have similar bed-way dimensions.

- They are both compatible with the clutch.

- They both have a wheel guard and a belt guard.

Differences between Myford ML7 and Super 7

- The Super 7 lathe has a long slide, whereas the Ml7 is shorter.

- The nuts that hold the studs on the Ml7 are behind, whereas the Super 7 nuts have been moved to the front.

- The design of the pins was improved on the Super 7.

- The Super 7 has a fitted clutch, whereas, on the Ml7, you have it as an optional accessory.

- The Ml7 models have 1/3 and ½ hp motors, whereas the Super 7 has a 0.75 hp motor.

- The Super 7 has a unique built-in oiler, whereas the Ml7 has a standard oiler.

Cost

The Ml7 is under 1,000, whereas the Super 7 is under 2,000. That makes the Ml7 more affordable than the Super 7.

Verdict on the Myford ML7 vs Super 7

You might choose the Myford Super 7 lathe due to the higher speed range. The durable spindle bearings, powerful motor, and automatic ejecting tailstock help. The clutch system is built-in rather than on the Ml7, which is optional. The top makes a 360-degree rotation. Yet, it tends to make a rattling noise due to the clutch. The Ml7 model is an early design that is straightforward. It does not make noise. You can attach the clutch system or not. If you have a tight budget, that is the ideal lathe machine. Yet, it is not the lathe machine for higher speeds. Considering your needs, I am sure you have your decision already.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024