Lathe machine vs Milling machine

What is the difference between a lathe and a milling machine? Both mill and lathe machines shape and cut materials, but they are different machines designed for specific materials and cutting operation types.

The two products differ in their operation, size, shape, and performance. The difference is that the lathe does not have a rotating cutting tool, while the milling machine does. Below, you will learn more about how these two products work, their weaknesses, and their strengths. Let us take a look at milling machine vs. lathe.

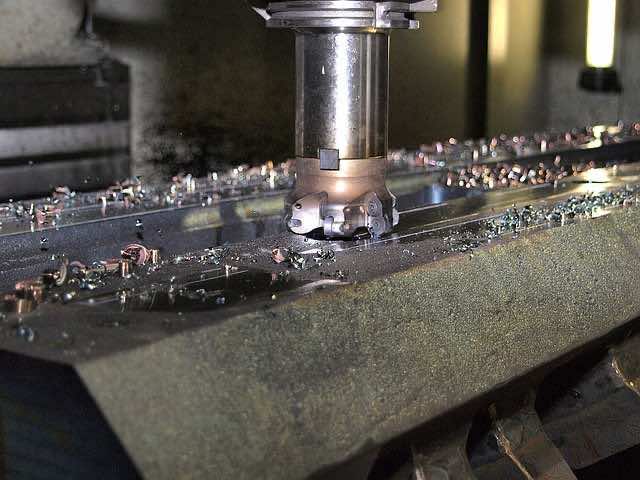

Milling Machine

The Milling machine removes material from a workpiece. The process includes taking the workpiece to the cutting tool. The Milling machine from the Lathe has a cutting tool with many blades.

The cutting tool is a point form. The Milling machine, like the lathe machine, comes in two forms: the Face milling machine and the Peripheral milling machine. The difference between these two is in the cutting action. When using Face milling, the cutting action occurs around the outside of the cutting tool.

When you use a Peripheral milling machine, the cutting process is across the cutting tool’s circumference. The machine varies in price depending on the cutting tools and other features you will improve. It is very likely that the Milling machine works on a wider range of materials than a lathe machine.

Pros

- Versatile

- Durable construction

- Flexible computer controls

- Accurate cuts

- Multiple cuts

Cons

- Heavy

- Pricey

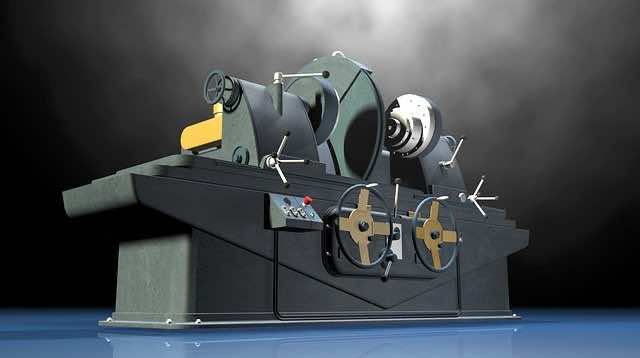

Lathe

A Lathe is a machine used to shape material. Two types of lathes are used on different materials. The Wood lathe only works on wood. The chances are slim that you can successfully use it on hard materials such as metal. You may use it on plastic. The metal lathe is the universal machine you can use for any material.

It has a hardened cutting tool that makes it easier and faster to cut through metal. It is a powerful machine with a heavy-duty motor. A Lathe has multiple parts, including a tailstock, headstock, carriage, bed, etc. Shaping material involves rotating metal or wood against a cutting tool, which has a single blade.

The workpiece needs to be fixed onto the machine. The cutting tool does not move or rotate. The wood lathe is lightweight and smaller. This is why metal lathes must be mounted, as they are heavy.

The lathe machine is characterized by a process called turning. It is ideal for parts that take up the cylinder shape. Other processes take place when using the Lathe machine, including threading, drilling, boring, and many more.

Pros

- Affordable

- Solid

- Fast

- Accurate

- Requires minimum operators

Cons

- Requires constant maintenance

- It is selective

Main Features

- Headstock

- Tailstock

- Spindle

Milling machine

Column and Base

The column and base are the sources of support for a milling machine. The column rests on the base, which has a small oil tank and a pump that keeps the machine lubricated.

Table

The rectangular base on the saddle conveniently keeps all your additional equipment closer. It comes with T-slots that can keep your jigs. You can choose to operate it using your own hands or by power.

Spindle

The shaft you hold when driving the cutting tool is the spindle. It does not operate independently but is mounted onto the bearings. The electric motor drives it into motion.

Lathe

Bed

This is the base of the Lathe machine, where the headstock and carriage are. The carriage rests on top of the bed, just like the column rests on top of the base of a Milling machine. The bed is quite solid, so it withstands the pressure of the workload.

Toolpost

Unlike the Milling machine with a table that holds all your tools, the Lathe gives you a tool post. The tool post is located on top of the machine. It comes in three types: the ring and rocker tool post, square-head and quick change tool post.

Spindle

This is where the workpiece rotates. The workpiece rotates when using the Lathe machine, whereas the cutting tool rotates when using the Milling machine.

What could be better?

Milling machine

- It could have been better to work with if it was not complex. It is not always that an experienced user gets to have such a machine.

- The Milling machine could have been smaller, just like the Lathe, so it would not use more space in your garage.

Lathe

- The cutting tool could have been made with optional blades. The user might have been up for a machine that gives you choices regarding the shape and style of the cutting tool.

- Since the Lathe machine is limited to the type of material it works on depending on the mechanism, it might have been convenient to be a universal lathe machine.

Similar Features

- Both machines remove different types of material from a work-piece

- They use a cutting tool.

- Both machines can make the same cuts.

The key difference between lathe and milling machine

Cutting blade

The Milling machine’s cutting tool comes in two forms: multi-bladed or pointed. The lathe machine only has a single-bladed tool. Both machines can make the same cuts, but with a Lathe, it takes numerous setups for the same result.

Size

A Milling machine is taller than a Lathe. However, this does not mean that the Milling machine does not have smaller versions. The manufacturers are trying to make machines that do not occupy more space.

Method of operation

When using a Lathe, the workpiece rotates against the cutting tool. The cutting g tool is always stationary. The case is different for the milling machine. The cutting tool rotates while the workpiece remains motionless. Besides size and the blades, this is the main difference between the machines.

Performance

A Milling machine is a versatile tool. What makes this possible is its speciality in cutting tools. It has multiple styles of end mills. It is a more complex machine than a lathe.

Some parts and items are difficult to work on using a lathe. Unlike the Milling machine, trophies can be challenging when working with a Lathe machine.

Cost

Although the Milling machine attracts a steeper price range, it still has some affordable models. The cost is determined by the innovations that come with a certain model. Lathe machines are affordable. This does not mean that they are less in performance.

Final Verdict on mill vs lathe

We have covered the differences between lathes and milling machines. Knowing the differences between these machines is important so you can maximize their performance by working on the right art with the right tool. The lathe appears simple, affordable, and small, although it is limited in terms of the type of material and styles it can produce.

The milling machine can be expensive, but it is worth the cost. It is a versatile tool that can be more innovative than the lathe. The cutting tool has different shapes, allowing users to work on different styles. It is good for business. Therefore, I can only recommend the milling machine.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024