Why you need a table saw maintenance checklist

The world of table saws is big, and the difference between a well-maintained and an unmaintained table saw can be huge. That’s why you must create a checklist for maintaining your table saw. This will ensure that you do not leave anything out while maintaining your table saw. A good checklist makes it easier to delegate tasks without the fear of forgetting something.

We have included a checklist in this post, which you will explain in detail.

First, is it time for the blade sharpening? Also, pay attention to the safety precautions.

Second, does the saw need a new blade? If there is a problem with the blade that needs replacing, you need to handle that without an entire afternoon of work.

Third, do you have a blade guide installed? An essential part of any table saw maintenance checklist is to ensure that all elements of your table saw are working as they should.

The aim should always be to keep all parts of the table saw in top shape.

Tools required for table saw maintenance

When doing maintenance on your table saw, having the appropriate tools on hand is a good idea. I would recommend having a full toolbox with various sizes of spanners to adjust nuts and bolts. Screwdrivers would also help.

List of Table Saw Parts to maintain:

- Mitre fence

- Sliding Mitre table

- Throat Plate

- Riving Knife

- Blade Guard

- Rear Rail

- Accessory Table

- Front Rail

- Bevel Scale

- Switch

- Blade Adjusting Handle

- Saw Blade

- Locking Clamps

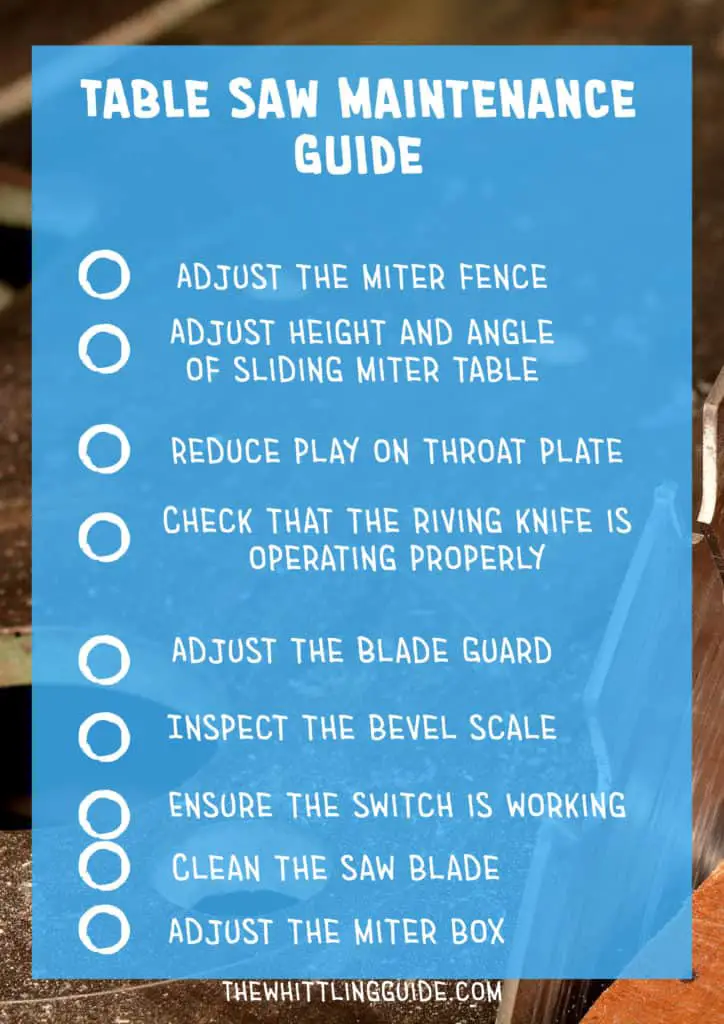

Table Saw Checklist

Mitre fence

The miter fence will need to be adjusted frequently as table saws are used. Table saws will have lower fences than jointer/planers, resulting in more cuts with the miter fence in the same time frame.

Sliding Mitre table

The sliding miter table is another important table saw part to maintain. You can adjust the height and angle of the blade and fence. This is a tool where any slop can be a problem, so it needs attention to ensure it is working at its peak performance level. To ensure that you can do this properly, get yourself a set of woodworking vice grips for your table saw and ensure they are working properly to give you control over your work surface.

Throat Plate

The throat plate is also a big trouble spot if you don’t have a miter gauge installed. You must adjust it often to ensure that the blade reciprocates back and forth without too much play in the miter slots.

Riving Knife

The riving knife needs constant monitoring for proper operation. You will need to pay close attention to this part to ensure that it is not damaged and properly cleaned as necessary. The riving knife will need to be adjusted with the blade height, so you must consider it when performing these tasks. [NOTE: The term “riving knife” refers to the thin metal at the end of saw blades which helps guide it sideways across cut wood.

Blade Guard

The blade guard is another important part of a table saw. It protects the operator around the blade and the table from accidental injury. It can be adjusted up and down as well as forward and backwards to suit your needs.

Rear Rail

The rear rail holds the fence, miter gauge, miter gauge, and other accessories on your table saw. Like all other machine parts, it needs frequent attention to ensure that it works at its best performance level.

Accessory Table

The accessory table is another part of the table saw that needs to be monitored and adjusted regularly. You can use it to hold tall workpieces such as framing lumber or trim pieces, which will need to be held in place so that they do not interfere with the blade and the fence.

Front Rail

The front rail holds your miter gauge, miter stop, accessories, and anything else you may want to use on your table saw. The front rail can also help hold workpieces in place as you are cutting without interfering with the blade or fence.

Bevel Scale

The bevel scale can affect the way your table saw cuts. It will be off for both angles that can be cut, resulting in a less than satisfactory cut. It is important to regularly monitor your bevel scale to ensure it works correctly before every use.

Switch

The switch on your table saw must always be turned off when not in use, and you must never work on or near a live circuit with the power turned on. Use care anytime you are dealing with the power in your table saw as an injury due to faulty equipment can lead to serious and expensive injuries.

Blade Adjusting Handle

The adjusting handle raises and lowers your table saw’s blade. This is done with a locking bar that holds the blade at the height you want to cut. This is another part that requires regular adjustments, especially cutting different materials.

Saw Blade

The saw blade is what does all of the cutting in your table saw. It needs to be kept sharp and clean and should not have any chips or cracks on it as this can cause damage to the wood that you are cutting and make a dangerous situation for the operator.

Locking Clamps

The locking clamps hold planks of wood or other items in place while cutting them. They need to be adjusted frequently to ensure that they do not loosen up while cutting, as this can cause the material you are trying to move around and potentially get caught between the table saw blade and fence.

Mitre Box

The miter box is built into your table saw’s cabinet and is used for cutting angles on one side of a piece of wood without moving it to create a 90-degree angle with your miter gauge. This requires constant monitor and adjustment because how far the sides of the board are set can affect how closely they match up against each other once it is cut.

Reducing the amount of dust liberated during assembly/disassembly.

Only tighten the bolts back up to the point that they stop turning completely. If you need to loosen them, use a hex key instead of a wrench, and retighten only as much as needed. Don’t over-tighten them!

For large workpieces, it may be easier to assemble or disassemble the table saw in stages and remove one half at a time (using a long pipe). Ensure that all parts are secured firmly (with screws or glue) before moving on to the next step.

A full wipe

Beyond the other tasks, giving your table saw a good wipe is always ideal. This gets rid of any debris or build up. In addition, it’s important to keep your tool in good working order.

Like collisions between drivers and objects used frequently, table saws quickly become the primary cause of injuries. Some of these injuries can be more serious than others.

An example is a wood splitter injury involving an accident between a wood splitter and you. In most situations, injuries are either caused by a misaligned blade or not tightening the belt properly (loosening).

References

https://www.ehow.com/how_8347806_repair-table-saw-lever.html

https://www.kapeldesigns.com/2010/04/table-saw-is-it-worthwhile.html

https://www.boschpowertools.co.uk/wiki/index.php?title=Table_Saw_-_Safety_and_Maintenance

https://www.powertooladvice.com/tablesaw-safety/

https://www.safetyhope.com/blogs/2012/10/table-saw-accident

https://www.leevalley.com/ blogs /woodworking /entry-12388220 -1814080475

https://www.lawnmartsolutions .com/blog_posts_tablesaws -and-your-family-339872.html

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024